The marine industry's evolution toward advanced materials has positioned EVA foam decking as a cornerstone solution for B2B shipyard operations and retrofit initiatives. This specialized flooring technology addresses critical challenges in commercial maritime environments, from slip resistance to chemical durability. Modern shipyards require materials that can withstand harsh marine conditions while providing superior performance across diverse vessel types and operational requirements.

Commercial marine contractors increasingly recognize that traditional decking materials fall short of meeting contemporary standards for safety, maintenance efficiency, and long-term cost effectiveness. The shift toward synthetic alternatives represents a fundamental transformation in how B2B marine professionals approach vessel construction and refurbishment projects. Understanding the specific advantages of advanced foam decking systems becomes essential for contractors managing large-scale maritime operations.

Technical Specifications and Performance Characteristics

Material Composition and Structural Properties

EVA foam decking consists of ethylene-vinyl acetate copolymer, engineered to deliver exceptional flexibility while maintaining structural integrity under marine stress conditions. The closed-cell foam structure provides inherent water resistance and prevents moisture infiltration that commonly compromises traditional wooden decking systems. This composition ensures dimensional stability across temperature fluctuations typical in commercial marine environments.

The material's density typically ranges from 150 to 300 kg/m³, offering optimal balance between cushioning properties and load-bearing capacity. Advanced manufacturing processes incorporate UV stabilizers and marine-grade additives that extend operational lifespan significantly beyond conventional alternatives. These technical specifications directly translate to reduced maintenance cycles and lower total cost of ownership for B2B clients.

Adhesive Technology and Installation Efficiency

Self-adhesive backing systems integrated into modern EVA foam decking eliminate the need for specialized adhesives or mechanical fasteners during installation. This feature dramatically reduces labor costs and project timelines for shipyard contractors managing multiple vessel retrofits simultaneously. The pressure-sensitive adhesive maintains bond strength across marine temperature ranges while allowing for future removal without substrate damage.

Installation efficiency becomes particularly critical in commercial shipyard environments where vessel downtime directly impacts client profitability. The simplified application process enables contractors to complete decking installations with reduced crew requirements and shorter project schedules. Quality control measures during installation remain straightforward due to the material's forgiving nature and repositioning capabilities.

Operational Advantages in Commercial Marine Applications

Safety Enhancement and Risk Mitigation

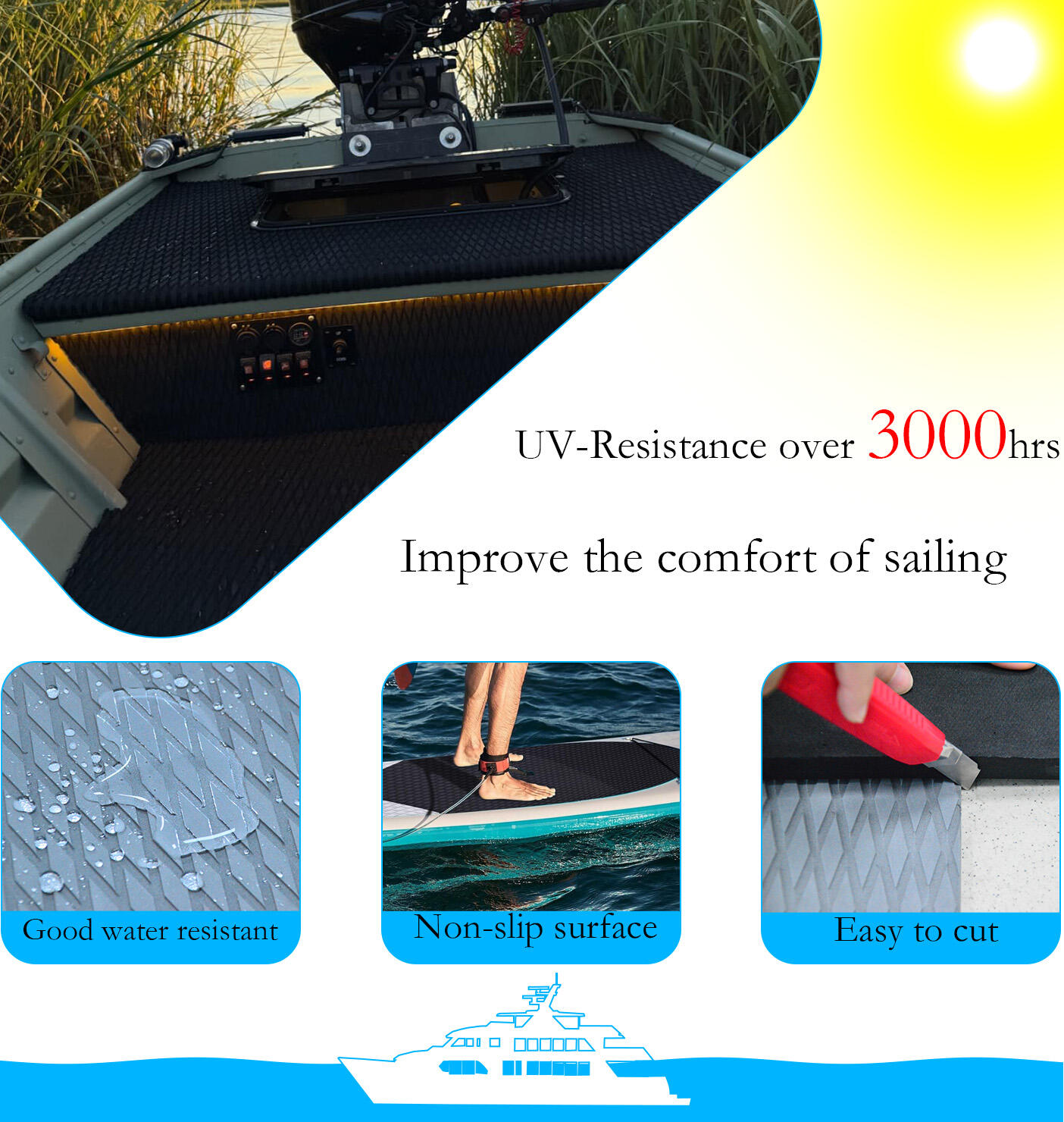

Non-slip surface textures engineered into EVA foam decking provide superior traction compared to traditional materials, especially when wet conditions prevail on commercial vessels. The material's cushioning properties reduce impact injuries from falls while maintaining adequate firmness for heavy equipment operation. These safety characteristics directly address liability concerns and insurance requirements common in B2B marine contracts.

Thermal insulation properties of EVA foam decking reduce surface temperatures in direct sunlight, preventing burn injuries to crew members working barefoot or in minimal footwear. The material remains comfortable to touch even after prolonged solar exposure, unlike metal or composite alternatives that can reach dangerous temperatures. This characteristic proves particularly valuable for commercial vessels operating in tropical or desert marine environments.

Maintenance Requirements and Operational Efficiency

Chemical resistance properties enable EVA foam decking to withstand exposure to fuel spills, cleaning solvents, and saltwater without degradation or staining. Regular maintenance requires only basic cleaning with standard marine detergents, eliminating the need for specialized treatment products or refinishing procedures. This simplified maintenance protocol reduces operational costs and minimizes vessel downtime for routine upkeep.

The material's resistance to marine growth and biological fouling prevents the accumulation of algae, barnacles, and other organisms that commonly affect traditional decking materials. This characteristic maintains hygienic conditions while preserving the decking's aesthetic appearance throughout extended service periods. Commercial operators benefit from reduced cleaning frequency and lower maintenance labor costs compared to conventional alternatives.

Economic Impact and Return on Investment Analysis

Initial Cost Considerations and Budget Planning

Material costs for EVA foam decking typically exceed traditional alternatives in initial procurement, but comprehensive lifecycle analysis reveals superior economic value through reduced maintenance expenses and extended replacement intervals. B2B procurement managers must evaluate total project costs including labor, materials, and future maintenance requirements to accurately assess economic impact. Volume purchasing agreements with manufacturers often provide significant cost advantages for contractors managing multiple vessel projects.

Installation cost reductions offset higher material expenses through simplified application procedures that require fewer skilled technicians and reduced project timelines. The elimination of substrate preparation requirements common with traditional materials further reduces labor costs and project complexity. These factors combine to create favorable economic conditions for contractors bidding on competitive commercial marine projects.

Long-term Value Proposition and Asset Protection

Durability characteristics of EVA foam decking extend operational lifespan to 8-12 years under normal commercial marine conditions, compared to 3-5 years typical for traditional materials. This extended service life reduces replacement frequency and associated vessel downtime costs that impact commercial operations. The material's resistance to UV degradation, chemical exposure, and physical wear maintains appearance and performance throughout the service period.

Asset protection benefits include prevention of substrate damage from water infiltration and reduced structural maintenance requirements over the vessel's operational lifetime. The decking system's ability to conform to irregular surfaces and absorb minor impacts protects underlying hull and deck structures from damage that could require costly repairs. These protective characteristics contribute significantly to overall vessel value retention and operational reliability.

Industry Applications and Market Segments

Commercial Fishing and Working Vessels

Commercial fishing operations require decking materials that withstand constant exposure to saltwater, fish processing chemicals, and heavy equipment operation. EVA foam decking provides the necessary chemical resistance while offering superior grip for crew safety during wet conditions. The material's ability to cushion impacts from dropped equipment and tools reduces damage to both the decking surface and valuable fishing gear.

Working vessels including tugboats, supply ships, and offshore support platforms benefit from the material's durability under extreme operational conditions. The non-marking properties prevent scuffing from heavy equipment while maintaining professional appearance standards required in commercial marine environments. These characteristics make EVA foam decking particularly suitable for vessels requiring frequent deck equipment repositioning and heavy cargo handling.

Passenger Vessels and Charter Operations

Passenger safety requirements in commercial marine operations demand decking materials that provide reliable traction while maintaining comfortable walking surfaces. EVA foam decking meets these requirements while offering aesthetic flexibility through various color and texture options. The material's quiet operation reduces noise transmission that can affect passenger comfort in enclosed spaces.

Charter vessel operators benefit from the material's resistance to staining from food spills, beverages, and sunscreen products commonly encountered in passenger service. Easy cleaning procedures maintain hygiene standards while preserving appearance throughout busy charter seasons. The material's UV resistance prevents fading and discoloration that could negatively impact customer perceptions and vessel marketability.

Installation Procedures and Technical Requirements

Surface Preparation and Substrate Compatibility

Proper substrate preparation ensures optimal adhesive bonding and long-term performance of EVA foam decking installations. Acceptable substrates include fiberglass, aluminum, steel, and properly prepared wood surfaces that provide stable foundations for the decking system. Surface cleaning removes contaminants including grease, salt deposits, and previous coating residues that could compromise adhesive performance.

Temperature and humidity conditions during installation significantly impact adhesive activation and bonding strength. Optimal installation occurs at temperatures between 60-80°F with relative humidity below 70% to ensure proper adhesive curing. Contractors must plan installation schedules around weather conditions and provide controlled environments when necessary to achieve specification-compliant installations.

Quality Control and Performance Verification

Installation quality verification includes adhesion testing at regular intervals across the decked surface to ensure uniform bonding strength. Edge sealing procedures prevent water infiltration at seams and perimeter areas that could compromise long-term performance. Proper installation documentation provides warranty coverage and maintenance guidance for vessel operators.

Post-installation inspection procedures verify surface flatness, seam integrity, and overall appearance quality before project completion. Any installation defects require immediate correction to prevent future performance issues and maintain warranty coverage. Quality control measures protect both contractor reputation and client satisfaction in competitive B2B marine markets.

Environmental Considerations and Sustainability

Material Recyclability and Disposal Options

EVA foam decking materials offer recycling opportunities through specialized plastic processing facilities that handle thermoplastic elastomers. End-of-life disposal considerations become increasingly important as environmental regulations tighten in commercial marine industries. Proper disposal planning reduces environmental impact while potentially recovering material value through recycling programs.

Manufacturing processes for quality EVA foam decking increasingly incorporate recycled content and environmentally responsible production methods. These sustainability initiatives align with corporate environmental policies common among major commercial marine operators. Material selection decisions that prioritize environmental responsibility can enhance contractor competitiveness in environmentally conscious market segments.

Chemical Impact and Marine Ecosystem Protection

Non-toxic formulations in modern EVA foam decking prevent leaching of harmful chemicals into marine environments during normal use and maintenance procedures. This characteristic addresses environmental compliance requirements and supports sustainable marine operations. The material's resistance to degradation reduces microplastic generation compared to some alternative synthetic materials.

Cleaning product compatibility ensures that routine maintenance procedures using biodegradable marine detergents do not compromise material performance or environmental safety. This compatibility supports green cleaning initiatives while maintaining operational efficiency. Environmental impact assessments favor EVA foam decking over traditional materials requiring toxic preservation treatments or frequent replacement cycles.

FAQ

What is the expected lifespan of EVA foam decking in commercial marine applications

EVA foam decking typically provides 8-12 years of reliable service in commercial marine environments when properly installed and maintained. Actual lifespan varies based on usage intensity, environmental conditions, and maintenance practices. Regular cleaning and periodic inspection can extend service life beyond typical expectations while maintaining optimal performance characteristics throughout the operational period.

How does EVA foam decking compare to traditional teak or composite alternatives

EVA foam decking offers superior slip resistance, lower maintenance requirements, and better thermal comfort compared to traditional teak or composite materials. While initial material costs may be higher, reduced installation labor and eliminated ongoing maintenance expenses typically provide better total cost of ownership. The synthetic material eliminates concerns about wood sustainability and composite delamination common with traditional alternatives.

Can EVA foam decking be installed over existing deck surfaces

Yes, EVA foam decking can be successfully installed over most existing deck surfaces including fiberglass, metal, and properly prepared wood substrates. The self-adhesive backing system eliminates the need for mechanical fasteners that could compromise existing deck integrity. Proper surface preparation including cleaning and minor repair work ensures optimal adhesion and long-term performance over existing substrates.

What maintenance procedures are required for EVA foam decking systems

Routine maintenance involves regular cleaning with mild marine detergents and fresh water rinse to remove salt deposits and surface contaminants. Monthly inspection of seams and edges helps identify any issues before they develop into significant problems. Annual professional inspection and minor repair work when needed maintains optimal performance and appearance throughout the service life of the decking system.

Table of Contents

- Technical Specifications and Performance Characteristics

- Operational Advantages in Commercial Marine Applications

- Economic Impact and Return on Investment Analysis

- Industry Applications and Market Segments

- Installation Procedures and Technical Requirements

- Environmental Considerations and Sustainability

- FAQ