A reliable EVA marine flooring manufacturer should possess strong factory capabilities, R&D and design capabilities, professional staff, and excellent after-sales service. Choosing the right EVA marine flooring manufacturer is a critical step for boat builders, yacht designers, and marine distributors. While many suppliers offer EVA foam products, the true differences lie beneath the surface. A proper capability assessment helps you identify a manufacturer that can consistently deliver quality, precision, and long-term support.

Factory Capabilities: Main Equipment and Customization Options

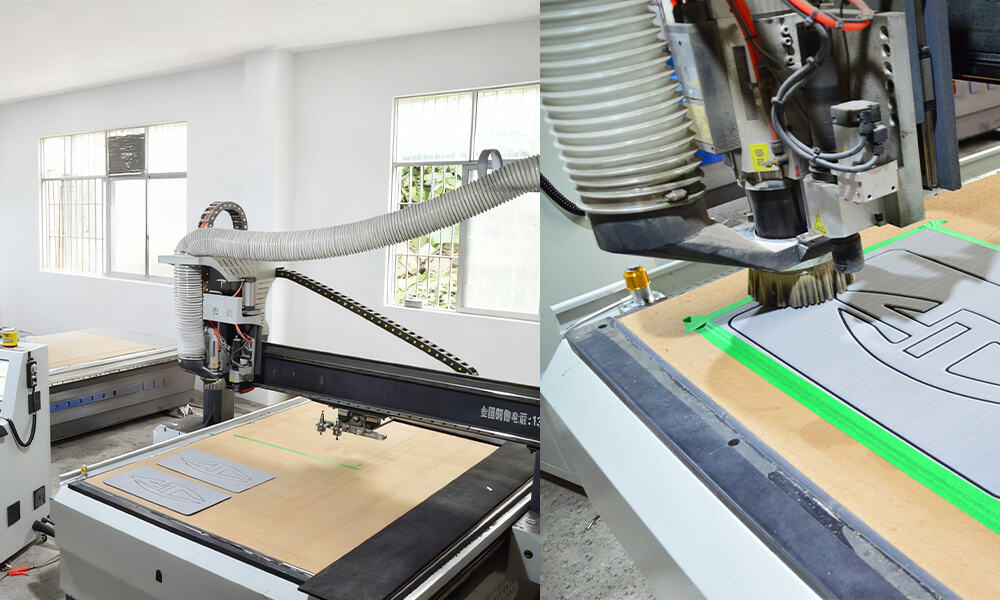

A reliable supplier should possess a variety of equipment, including: brushing machines, multiple CNC engraving machines, laser engraving machines, embossing machines, and both manual and automatic die-cutting machines.

YCDECK Factory Advantages:

YCDECK, as an established factory with 30 years of experience, boasts complete production equipment and extensive professional expertise.

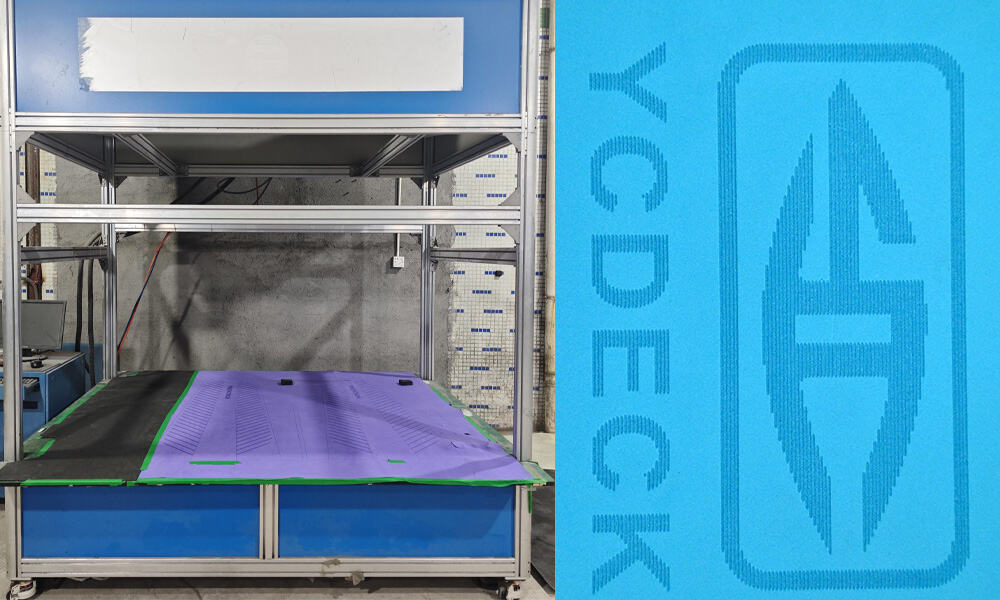

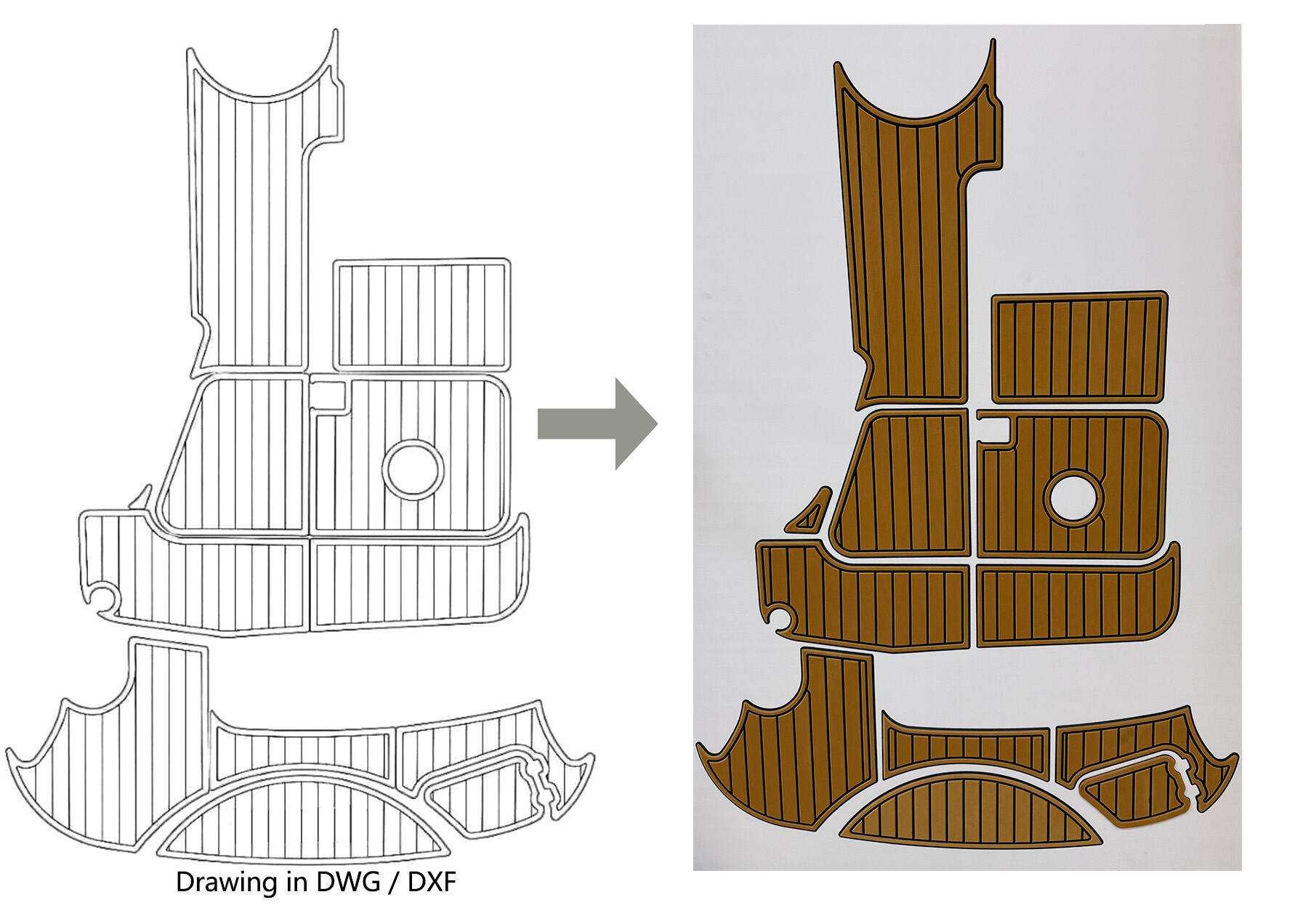

CNC engraving machines and laser engraving machines can be used to customize logos or create complete boat kits based on the drawings you provide.

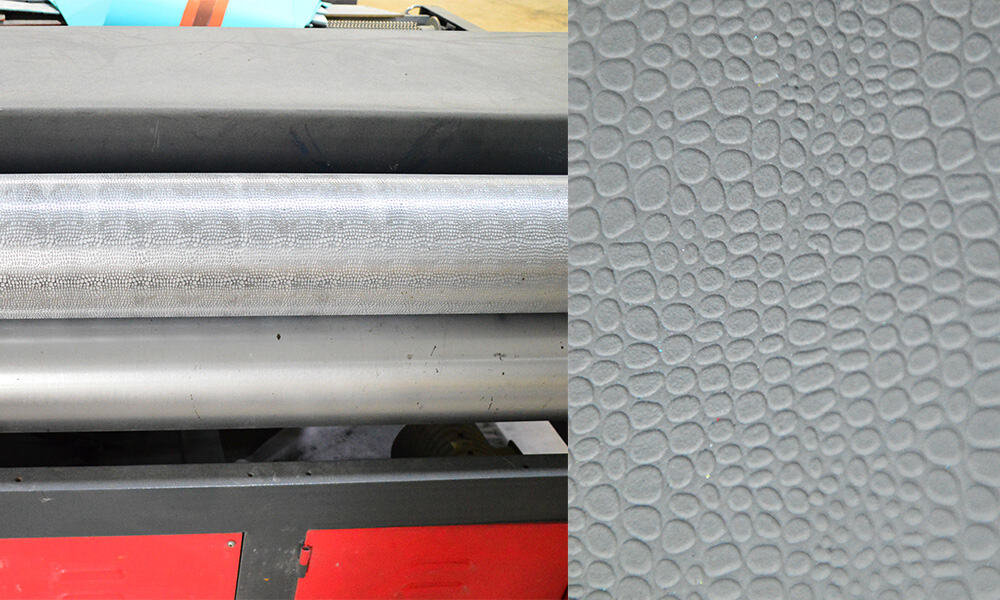

The embossing machine can be customized with specialized rollers according to your needs, allowing you to create custom patterns on EVA sheets.

Design capabilities: Professional graphic designers and a powerful database.

For individual users, EVA marine flooring needs to be not only practical but also aesthetically pleasing. For shipyards, factories with a database of ship designs are more efficient and convenient, as they don't need to measure the vessels; production can begin directly after verification.

YCDECK has dedicated designers who can design patterns for you. Furthermore, YCDECK has a database of over 2,000 boat designs. Of course, if your boat design is not in our database, we can guide you through the measurement process, and we can still manufacture the product based on the drawings you provide.

Professional team: Research and development and production

A reliable EVA marine decking manufacturer should possess not only factory capabilities but also strong R&D capabilities and a professional team.

YCDECK is committed to providing high-quality products for marine enthusiasts, constantly upgrading its material production. Currently, YCDECK marine flooring has a hardness of 65±3 Shore C and UV resistance exceeding 3000 hours.

YCDECK's experienced factory staff have decades of production experience in the field of EVA marine anti-slip mats. They are proficient in EVA/PE material knowledge and the precise control of production equipment, ensuring product quality.

YCDECK has professional engineers who can measure and draw based on drawings or plastic templates provided by customers, and then proceed with production after confirmation with the customer.

Quality Inspection and After-Sales Service

Excellent products and after-sales service reflect the customer's long-term trust in the manufacturer and the manufacturer's commitment to its customers.

Other manufacturers may source their materials from multiple EVA foam factories, which can lead to color variations in their boards. YCDECK integrates EVA material foaming and marine flooring production, so customers don't have to worry about color differences in the boards we provide. Furthermore, we employ deaf individuals for quality control; their focus on the task, free from distractions, ensures meticulous product inspection. This not only demonstrates our commitment to product quality but also our care for people with disabilities.

YCDECK provides a 12-month product warranty, with professional staff available to quickly address any product issues.

Conclusion: Capability Matters More Than Price

When choosing an EVA marine flooring manufacturer, price should never be the only factor. A comprehensive capability assessment—covering factory strength, design ability, professional personnel, material expertise, and after-sales support—helps ensure reliable quality and long-term success.

The right manufacturer is not just a supplier, but a partner who supports your projects from design to delivery and beyond.

FAQ

- Can YCDECK EVA mat be applied over existing non-skid?

YCDECK EVA mat adheres very well to most molded-in non-skids and properly applied and maintained aggregate type non-skid paints, as long as the surface is cleaned properly prior to installation.

- Can you do custom logos?

Yes. YCDECK support full OEM service, including logos, patterns, thickness, unique anti-slip texture, sharp edges etc.

- What is the cost per square metre?

This would depend on a number of factors: the complexity (number and area) of the logos, the time required for digital processing and machining, and the total surface area.

- What is the lifespan?

YCDECK EVA mat is very durable and specifically designed for marine environments, standing up to harsh weather conditions. It comes with a 3-year warranty, under proper care, it can last well beyond three years. Covering the mats when not in use will significantly extend their lifespan. treat them similarly to the way you treat your vinyl seats or other soft materials in your boat.