Mūsdienu jūras grīdas risinājumu izpratne

Ja vēlaties uzlabot kuģa estētisko un funkcionālo izskatu, viens no svarīgākajiem lēmumiem, ko esat izdarījuši, ir izvēlēties pareizo kuģa grīdas segumu. Ideāls kuģa grīdas segums ne tikai nodrošina pasažieriem drošu un komfortabli virsmu, bet arī ievērojami palielina kuģa kopējo vērtību un izklaidi. Šobrīd tirgū ir pieejams iespaidīgs materiālu klāsts, kas apvieno izturību ar stilu un nodrošina, ka kuģis izskatās lieliski, izturot nelabvēlīgu jūras vidi.

Jūras vides rada unikālus izaicinājumus, ar kuriem parastiem grīdas materiāliem vienkārši nav iespējams tikt galā. Lai gan kuģu grīdas segumi pastāvīgi ir pakļauti sālsūdens un UV spīdumiem, lai gan ir jāapstiprina, ka tie ir neplīstoši un viegli uzturami, tiem ir jāatbilst stingriem prasībām, saglabājot visu visu vizuālo izskatu. Izskatīsim visvairāk izcilus piedāvājumus mūsdienu kuģu īpašniekiem, kas nevēlas kompromēt ar funkcionalitāti vai estētiku.

Augstas kvalitātes sintētiskie materiāli jūras lietošanai

Jūras klases vinila un PVC iespējas

Jūras klases vinils ir revolucionizējis laivu grīdas pārklājumus ar izcilu izturības un stila kombināciju. Šis sintētiskais materiāls piedāvā lielisku pretestību pret ūdeni, UV stariem un notrieptiem, tādēļ tas ir lielisks risinājums gan iekštelpu, gan ārtelpu laivu grīdām. Mūsdienu jūras vinils ir pieejams daudzveidīgā krāsu un tekstūru klāstā, tostarp ar realistisku koka struktūru, kas imitē teiku, neprasot tās uzturēšanu.

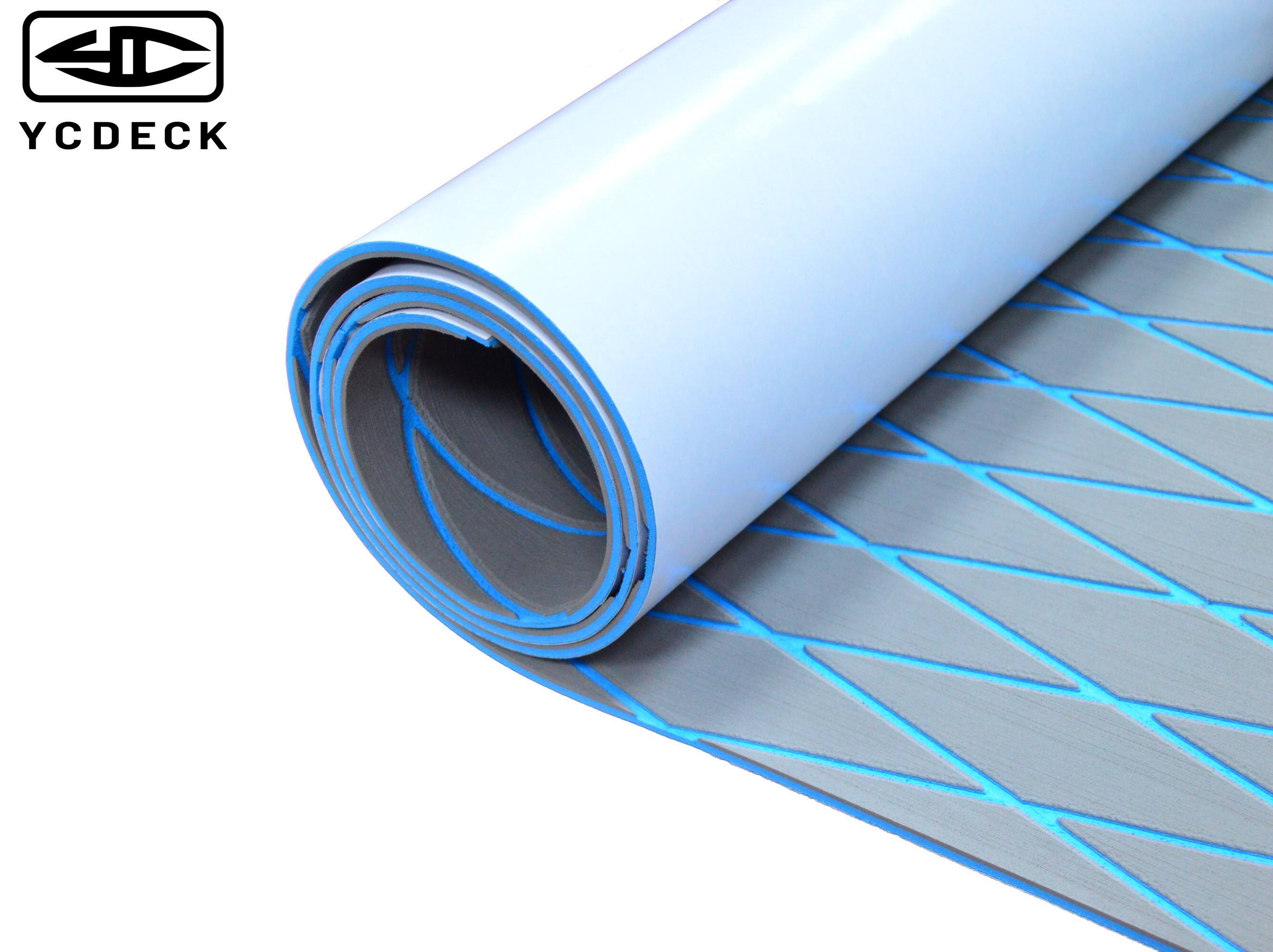

PVC laivu grīdas pārklājumi ir vēl viens inovatīvs sintētiskais risinājums, kas iegūst popularitāti starp laivu īpašniekiem. Šie materiāli izmanto sarežģītu kompozitmateriālu konstrukciju, radot izturīgu, vieglu virsmu, kas spēj izturēt intensīvu kājāmgājienu un jūras apstākļus. Daudzi PVC risinājumi ietver iebūvētu amortizāciju, kas uzlabo komfortu, saglabājot lielisku slīdēšanas pretestību pat mitrā stāvoklī.

Sintētiskie teika klāja risinājumi

Sintētiskais tiks ir kļuvis par revolucionāru alternatīvu tradicionālajai tika laivu grīdai. Šis materiāls saglabā īstā tika mūžīgo eleganci, vienlaikus novēršot daudzas tā trūkstošās puses. Mūsdienīgs sintētiskais tiks produkti nodrošina pārāku izturību pret noblaksnēšanos, traipu veidošanos un vēderēšanu, minimāli uzturējot pievilcīgu izskatu.

Jaunākie sintētiskā tika materiāli ietver uzlabotus UV stabilizatorus un krāsu caur konstrukciju, nodrošinot, ka to izskats saglabājas pat pēc gadu ilgas pakļaušanas smagiem jūras apstākļiem. Šie produkti piedāvā arī lielisku slīdēšanas pretestību un tos var pielāgot ar dažādām krāsu opcijām un rakstiem, lai izveidotu unikālus klāja dizainus.

Tradicionālie jūras transportlīdzekļu grīdas materiāli

Īstais tiks un cietkoksnes iespējas

Tradicijas tiks paliek par laivas grīdas zelta standartu, to vērtējot pēc tās dabiskās skaistuma un izcilās izturības. Šis klasiskais materiāls piedāvā iedzimtu mitrumizturību un satur dabiskus eļļas šķidrumus, kas palīdz aizsargāt pret puvi un sabrukšanu. Ar pienācīgu kopšanu tika grīda var kalpot desmitiem gadu, attīstot cienījamu sudrabainu patinu, ko daudzi laivnieki uzskata par ļoti pievilcīgu.

Citi cietskoki, piemēram, mahagoni un iroko, arī piedāvā lielisku izturību un estētisku pievilcību laivas grīdai. Šiem materiāliem nepieciešama lielāka kopšana salīdzinājumā ar sintētiskajiem variantiem, taču tie nodrošina neaizstājamu līmeni dabiskās skaistuma un elegances, ko daudzi laivnieki uzskata par liecību papildus pūlēm.

Jūras paklājs un tradicionālie materiāli

Jūras klasei atbilstošs paklājs joprojām ir populārs laivu grīdas seguma izvēles veids, īpaši iekštelpu kajītēm un pārsegtām zonām. Mūsdienu jūras paklāji izgatavoti no uzlabotiem sintētiskiem šķiedru materiāliem, kas noturīgi pret pelējumu un traipiem, vienlaikus nodrošinot lielisku komfortu zem kājām. Šie materiāli speciāli izstrādāti jūras vajadzībām, izmantojot pret UV starojumu noturīgas krāsvielas un ūdeni noturīgu pamatu.

Arī tradicionālie materiāli, piemēram, korķis un gumijas kompozīti, saglabā savu nozīmi noteiktos laivu grīdas seguma pielietojumos. Šie materiāli nodrošina dabisku triecienu absorbēšanu un komfortu, vienlaikus piedāvājot labu slīdēšanas pretestību. Pareizi noslēgti un uzturēti, tie var kalpot vairākus gadus jūras apstākļos.

Veiktspējas apsvērumi jūras grīdas segumiem

Ilgtspēja un izturība pret laika apstākļiem

Laivas grīdas materiāla izturība tieši ietekmē gan drošību, gan ilgtermiņa vērtību. Augstas kvalitātes laivas grīdai jābūt izturīgai pret degradāciju, kas rodas pastāvīgai saskarei ar siltu ūdeni, UV starojumu un temperatūras svārstībām. Materiāliem jāsaglabā strukturālā integritāte un izskats, neskatoties uz regulāru tīrīšanu ar spēcīgiem jūras klases tīrīšanas līdzekļiem un saskari ar zvejas piederumiem, klāja krēsliem un citām iekārtām.

Noturība pret laikapstākļiem sniedzas tālāk par vienkāršu ūdensnecaurlaidību — tā ietver materiāla spēju saglabāt savas īpašības ekstrēmu temperatūras maiņu, intensīvas saules gaismas un mainīga mitruma apstākļos. Labākās laivas grīdas iespējas ietver UV stabilizatorus un speciālas apstrādes metodes, kas novērš plaisāšanu, nobalēšanu un degradāciju šādos grūtos apstākļos.

Drošības un apkopes prasības

Drošības funkcijas, piemēram, slīdēšanas pretestība un siltuma izkliede, ir būtiski apsvērumi, izvēloties grīdas segumu laivām. Labākie materiāli nodrošina uzticamu saķeri gan mitrās, gan sausās apstākļos, vienlaikus paliekot komfortabli basām kājām. Daži jaunākās paaudzes materiāli iekļauj mikroskopisku strukturēšanu, kas uzlabo saķeri, neizveidojot raupjas virsmas, kuras varētu būt neērtas vai grūti tīrāmas.

Uzturēšanas prasības ievērojami atšķiras atkarībā no dažādiem laivu grīdas materiāliem. Kamēr dažiem sintētiskiem variantiem nepieciešama tikai regulāra tīrīšana ar ziepēm un ūdeni, tradicionālajiem materiāliem, lai saglabātu to aizsargīpašības un izskatu, var būt nepieciešams periodisks hermētisks noslēgums, eļļošana vai pārklāšana. Šo uzturēšanas prasību izpratne ir būtiska, lai pieņemtu informētu lēmumu, kas atbilst pieejamajam laikam un resursiem.

Uzstādīšana un izmaksu apsvērumi

Profesionāla instalācija vai pašinstalācija

Uzstādīšanas metode laivu grīdai var ievērojami ietekmēt gan sākotnējās izmaksas, gan ilgtermiņa veiktspēju. Profesionāla uzstādīšana nodrošina pareizu sagatavošanu, precīzu pieguļu un atbilstošu hermētiskumu, kas var pagarināt jūsu laivu grīdas kalpošanas laiku. Daudzas sintētiskas materiālu šobrīd piedāvā inovatīvas uzstādīšanas sistēmas, kas vienkāršo procesu, saglabājot profesionālas kvalitātes rezultātus.

Arī patstāvīgai uzstādīšanai piemērotas laivu grīdas iespējas kļūst arvien sofistikātākas, daži materiāli piedāvā savienojamos sistēmas vai līmlentu uzklāšanas metodes. Lai gan tas var samazināt sākotnējās izmaksas, ir ļoti svarīgi rūpīgi novērtēt, vai pašuzstādīšana ir piemērota jūsu konkrētajai situācijai un prasmju līmenim.

Ilgtermiņa vērtība un ieguldījumu atdeve

Novērtējot laivu grīdas iespējas, jāņem vērā gan sākotnējās izmaksas, gan ilgtermiņa vērtība. Augstākas kvalitātes materiāli bieži attaisno savas augstākās sākotnējās izmaksas, nodrošinot ilgāku kalpošanas laiku un samazinot uzturēšanas nepieciešamību. Kvalitatīva laivu grīda var ievērojami palielināt kuģa vērtību un pievilcību, kas ir īpaši svarīgi tiem, kas plāno nākotnē pārdot to atkārtoti.

Ieguldījumu atdeve ietver arī garantijas apjomu, aizvietošanas iespējamību un materiāla spēju saglabāt savu izskatu laika gaitā. Daži sintētiskie materiāli piedāvā izcilu garantiju un tos var daļēji nomainīt, ja tie ir bojāti, tādējādi nodrošinot papildu vērtību un mieru prātā.

Bieži uzdotie jautājumi

Cik ilgi parasti kalpo laivu grīda?

Laivu grīdas kalpošanas laiks ievērojami atšķiras atkarībā no materiāla izvēles un uzturēšanas. Ar augstu kvalitāti sintētiskie materiāli parasti kalpo 7–10 gadus ar pienācīgu aprūpi, savukārt rūpīgi uzturēts tikskoks var kalpot vairākas desmitgades. Regulāra uzturēšana un aizsardzība pret smagiem apstākļiem būtiski var pagarināt jebkura veida laivu grīdas kalpošanas laiku.

Kāda ir visizdevīgākā laivu grīdas iespēja?

Jūras klases vinila un PVC iespējas parasti piedāvā labāko līdzsvaru starp izturību un izmaksu efektivitāti. Lai gan to sākotnējās izmaksas ir vidējas, zemas uzturēšanas prasības un ilgs darbības laiks padara šos materiālus ilgtermiņā ekonomiski izdevīgas izvēles. Šie materiāli piedāvā arī lielisku pretestību bojājumiem un nolietojumam, samazinot nepieciešamību tos nomainīt.

Vai laivu grīdu var uzstādīt aukstā laikā?

Lielākajai daļai laivu grīdas materiālu uzstādīšanai nepieciešamas mērenas temperatūras, parasti no 50 līdz 80 °F (10–27 °C). Daudziem uzstādīšanai izmantotajiem līmēm un blīvējumu materiāliem nepieciešams noteikts temperatūras diapazons, lai tie pareizi sacietētu. Lai panāktu optimālus rezultātus, vienmēr konsultējieties ar ražotāja norādījumiem un apsveriet profesionālas uzstādīšanas iespēju piemērotos laika apstākļos.