Ewolucja rozwiązań podłogowych w branży morskiej

Przemysł morski doświadczył znaczącej przemiany w zakresie materiałów na pokład od ostatnich dziesięcioleci. Tradycyjne wykończenia pokładu z tekowego drewna, choć klasyczne i piękne, ustąpiły miejsca bardziej nowoczesnym i praktycznym rozwiązaniom. Wśród tych nowoczesnych alternatyw, podłogi z pianki EVA stały się najpopularniejszym wyborem wśród właścicieli łodzi i jachtów na całym świecie. Ten rewolucyjny materiał łączy doskonałą funkcjonalność z estetyczną atrakcyjnością, co czyni go idealnym rozwiązaniem dla środowisk morskich.

Niezbędne cechy podłóg z pianki EVA przeznaczonych do użytku morskiego

Doskonałe właściwości bezpieczeństwa i komfortu

Podłogi z pianki EVA zapewniają wyjątkowe właściwości antypoślizgowe, kluczowe dla bezpiecznego poruszania się po pokładzie zarówno w warunkach wilgotnych, jak i suchych. Właściwości amortyzujące materiału zmniejszają zmęczenie podczas dłuższego pobytu na pokładzie, a jego miękka powierzchnia zapewnia komfort przy chodzeniu. Te cechy czynią go szczególnie wartościowym podczas długich rejsów czy żeglugi po trudnych wodach.

Specjalny skład pianki EVA morskiej gwarantuje doskonałą przyczepność nawet w warunkach oddziaływania wody morskiej, co czyni ją znacznie bezpieczniejszą niż tradycyjne pokłady drewniane lub syntetyczne alternatywy. Ta ulepszona cecha bezpieczeństwa jest szczególnie ważna dla rodzin z dziećmi lub starszymi pasażerami na pokładzie.

Trwałość i odporność na warunki atmosferyczne

Środowiska morskie stwarzają wyjątkowe wyzwania dla materiałów podłogowych, wymagając niezwykłej trwałości i odporności na surowe warunki. Pianka EVA doskonale sprawdza się pod tym względem, oferując niezwykłą odporność na promieniowanie UV, działanie wody morskiej oraz wahania temperatury. Materiał zachowuje swoje właściwości konstrukcyjne i wygląd nawet po wielu latach ciągłego użytkowania.

W przeciwieństwie do drewnianych pokładów wymagających regularnej konserwacji i odnawiania powierzchni, podłogi z pianki EVA zachowują swój wygląd i funkcjonalność przy minimalnym nakładzie konserwacji. Ta trwałość przekłada się na długoterminową oszczędność kosztów oraz zmniejszone wymagania konserwacyjne dla właścicieli łodzi.

Różnorodność i atrakcyjność projektu

Opcje personalizacji

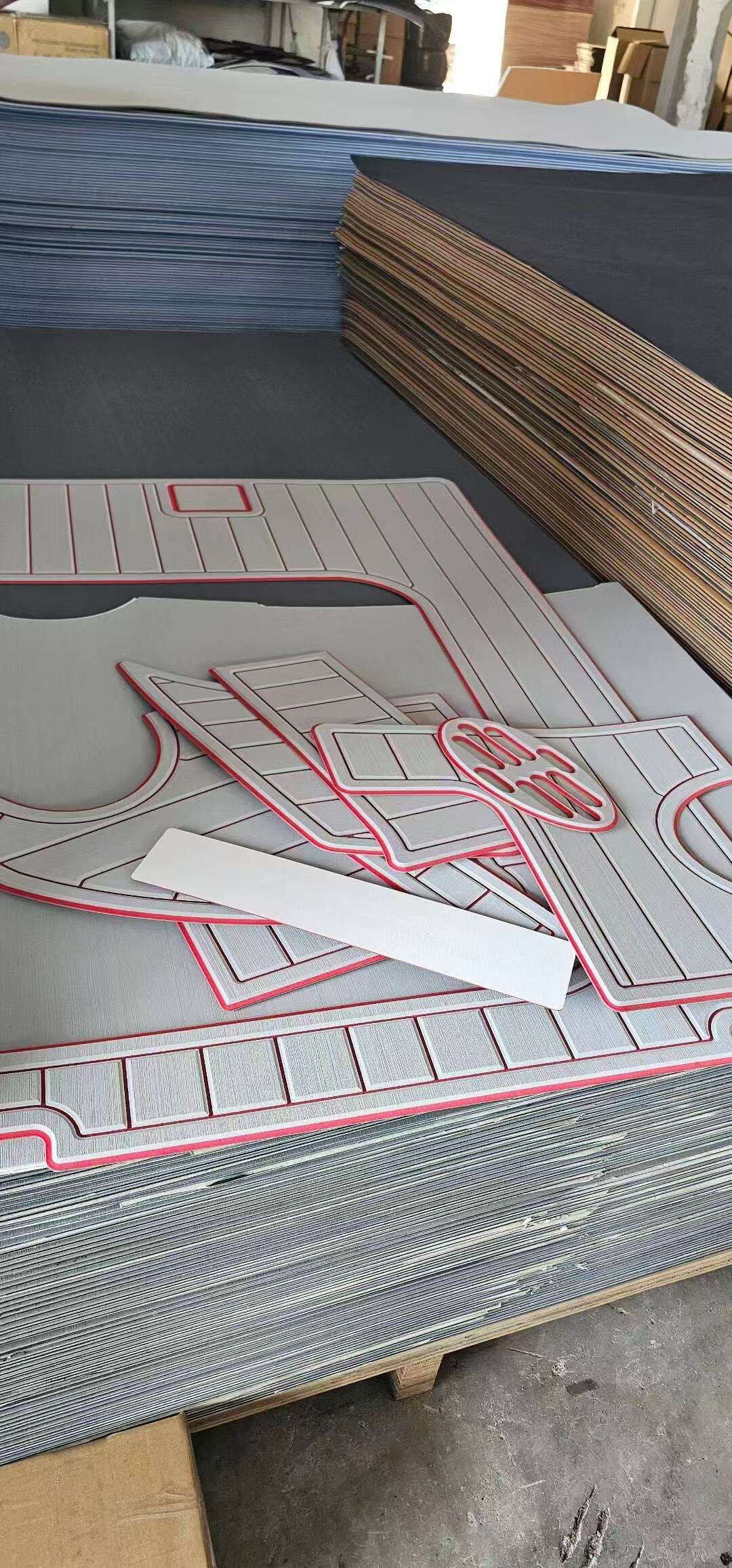

Nowoczesne podłogi z pianki EVA są dostępne w szerokim zakresie kolorów, wzorów i faktur, umożliwiając właścicielom łodzi tworzenie wyjątkowych wykończeń, które uzupełniają projekt ich jednostki. Wzory niestandardowe oraz logo można wkomponować w projekt podłogi, dodając indywidualny charakter wyglądu łodzi. Materiał ten można precyzyjnie przycinać i dopasowywać do dowolnego układu pokładu, zapewniając bezszwowe zamontowanie.

Możliwość łączenia różnych kolorów i wzorów otwiera kreatywne możliwości projektowe — od klasycznych rozwiązań naśladujących drewno tekowe po nowoczesne wzory geometryczne. Ta uniwersalność czyni podłogi z pianki EVA odpowiednimi zarówno dla tradycyjnych, jak i nowoczesnych projektów jednostek.

Profesjonalna instalacja i integracja

Proces instalacji podłogi z pianki EVA pokazuje jej praktyczne zalety. Materiał można precyzyjnie wycinać i dopasowywać do okolic elementów wyposażenia pokładu, zapewniając profesjonalny wygląd. Zaawansowane systemy klejące gwarantują trwałe przyłączenie do podłoża, pozwalając jednocześnie na późniejsze usunięcie lub wymianę w razie potrzeby.

Doświadczeni instalatorzy mogą tworzyć niespoiste przejścia między różnymi strefami łodzi, integrując praktyczne rozwiązania, takie jak kanały odpływowe i wykończenie brzegów. Taka dbałość o szczegóły poprawia zarówno funkcjonalność, jak i estetykę wykonania.

Korzyści dla środowiska i utrzymania

Aspekty ekologiczne

W miarę jak rośnie świadomość ekologiczna w przemyśle morskim, podłoga z pianki EVA wyróżnia się swoimi zrównoważonymi cechami. Materiał ten jest nadający się do recyklingu i ma minimalny wpływ na środowisko w porównaniu z tradycyjnym teakowym pokładem, który często wiąże się z wycinaniem rzadkich twardych gatunków drewna. Nowoczesne procesy produkcyjne pianki EVA koncentrują się na ograniczaniu śladu węglowego i stosowaniu ekologicznych metod produkcji.

Długa żywotność podłogi z pianki EVA dodatkowo przyczynia się do jej korzyści środowiskowych, zmniejszając potrzebę częstych wymian i związanego z tym zużycia zasobów. Wiele producentów oferuje obecnie programy recyklingu starych podłóg, wspierając inicjatywy gospodarki o obiegu zamkniętym.

Proste wymagania konserwacyjne

Praktyczne zalety w utrzymaniu czystości podłogi z pianki EVA czynią ją szczególnie atrakcyjną dla właścicieli łodzi. Codzienne czyszczenie wymaga jedynie mydła i wody, eliminując konieczność stosowania agresywnych chemikaliów lub specjalistycznych środków czyszczących pRODUKTY . Nieprzepuszczalna powierzchnia zapobiega przebarwieniom i ułatwia usuwanie rozlanych płynów.

W przeciwieństwie do drewnianej pokładu, która wymaga corocznych zabiegów konserwacyjnych i okresowego odnawiania wykończenia, podłoga z pianki EVA zachowuje swój wygląd przy minimalnym nakładzie interwencji. Zmniejszone obciążenie związane z konserwacją pozwala właścicielom więcej czasu spędzać na użytkowaniu swoich jednostek, a mniej na ich konserwacji.

Często zadawane pytania

Jak długo zwykle trwa podłoga z pianki EVA w zastosowaniach morskich?

Dzięki prawidłowemu montażowi i utrzymaniu pokrycie podłogowe z pianki EVA morskiego gatunku może służyć od 7 do 10 lat lub dłużej, w zależności od intensywności użytkowania i warunków ekspozycji. Materiał zachowuje swoje walory estetyczne i właściwości użytkowe przez cały okres eksploatacji, co czyni go opłacalnym długoterminowym inwestycją.

Czy pokrycie podłogowe z pianki EVA można montować na dowolnym rodzaju powierzchni łodzi?

Pokrycie podłogowe z pianki EVA można montować na większości powierzchni stosowanych w żeglarstwie, w tym na pokładach ze szkłoplastiku, drewna i metalu. Jednak powierzchnia musi być odpowiednio przygotowana i mieć solidną konstrukcję. Profesjonalny montaż zapewnia optymalne przyleganie i długą trwałość systemu podłogowego.

Co wyróżnia pokrycie podłogowe z pianki EVA spośród innych syntetycznych rozwiązań dla pokładów morskich?

Pokrycie podłogowe z pianki EVA wyróżnia się dzięki unikalnemu połączeniu komfortu, bezpieczeństwa i wytrzymałości. W przeciwieństwie do sztywnych materiałów syntetycznych, oferuje doskonałą amortyzację uderzeń oraz właściwości antywysiłkowe, jednocześnie zapewniając doskonały chwyt na mokrej powierzchni. Jest ono dOSTOSOWANIE opcje i łatwość konserwacji dodatkowo wyróżniają ją na tle alternatyw.