Selecting the right materials for custom boat flooring is crucial for ensuring durability, safety, and aesthetic appeal in marine environments. The harsh conditions aboard watercraft, including constant moisture exposure, UV radiation, salt corrosion, and temperature fluctuations, demand flooring solutions that can withstand these challenges while providing excellent traction and comfort. Professional marine contractors and boat owners alike must carefully evaluate material properties, installation requirements, and long-term maintenance considerations when planning flooring projects. Understanding the strengths and limitations of different flooring materials enables informed decision-making that maximizes both performance and value over the vessel's operational lifetime.

Marine-Grade EVA Foam Flooring Solutions

Properties and Performance Characteristics

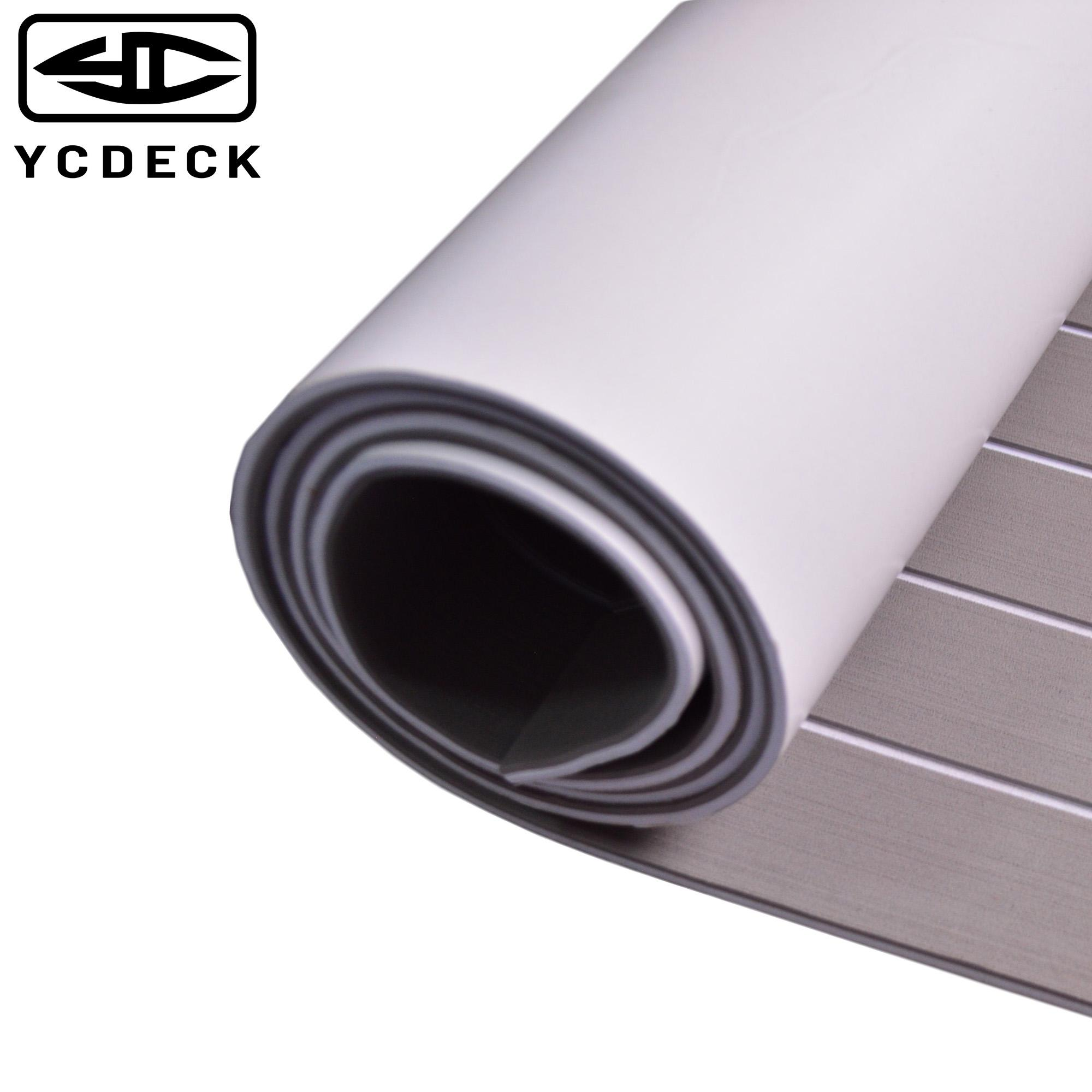

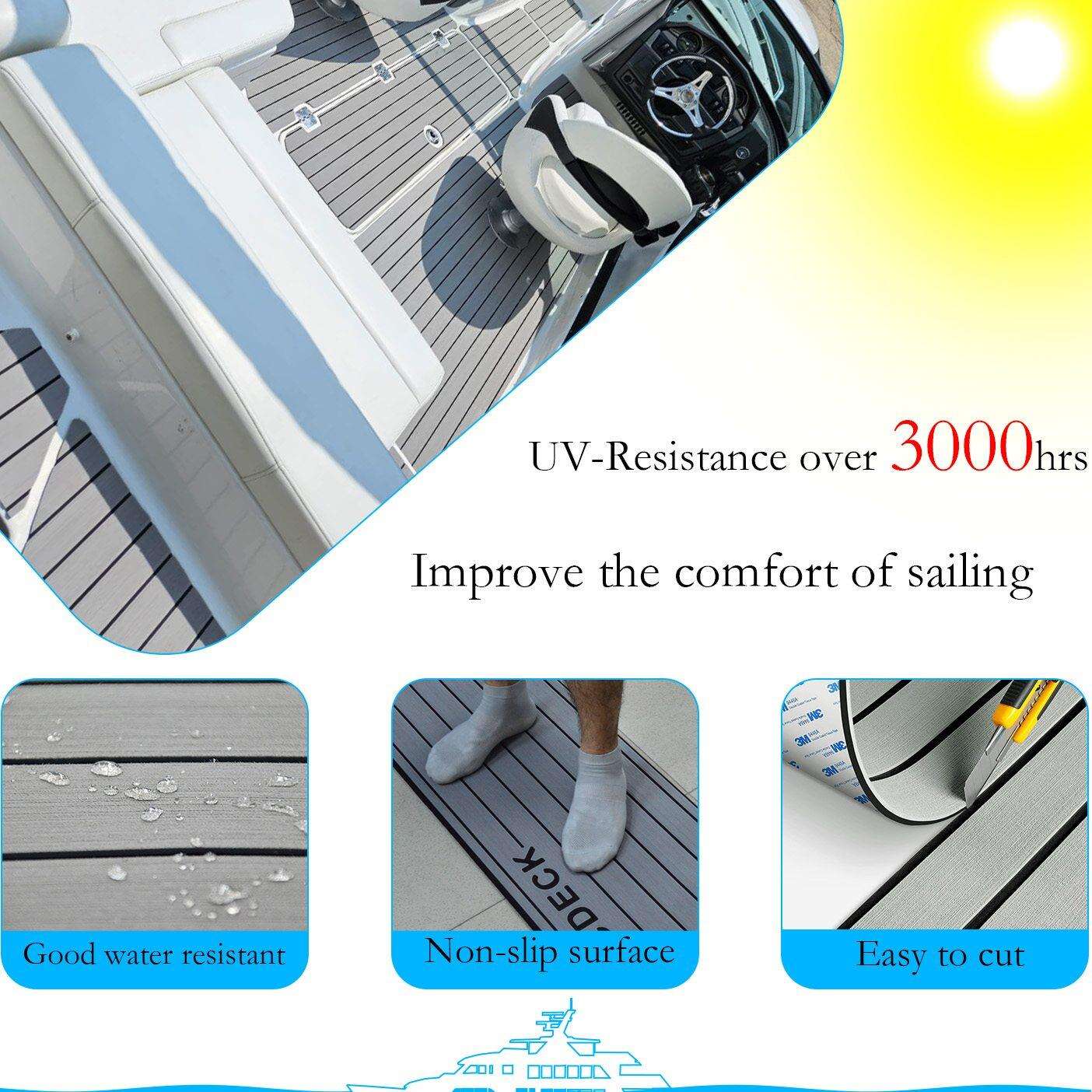

EVA foam has emerged as a leading choice for custom boat flooring applications due to its exceptional combination of durability, comfort, and water resistance. This closed-cell foam material exhibits remarkable resilience against marine conditions, maintaining its structural integrity even after prolonged exposure to saltwater, UV radiation, and temperature extremes. The material's inherent buoyancy provides additional safety benefits, while its cushioned surface reduces fatigue during extended periods on deck. EVA foam's non-porous nature prevents water absorption, eliminating the risk of mold, mildew, and bacterial growth that commonly plague traditional flooring materials in marine environments.

The flexibility of EVA foam allows for seamless integration into complex boat layouts, accommodating curved surfaces, irregular shapes, and tight spaces that characterize modern vessel designs. Professional installers appreciate the material's workability, as it can be easily cut, shaped, and fitted using standard marine construction tools. The surface texture of quality EVA foam products provides excellent slip resistance even when wet, addressing one of the primary safety concerns in marine flooring applications. Additionally, the material's chemical resistance ensures compatibility with common marine cleaning products and deck treatments without degradation or discoloration.

Installation Advantages and Techniques

EVA foam flooring systems typically feature adhesive backing that simplifies the installation process while ensuring strong substrate bonding. This self-adhesive property eliminates the need for messy marine adhesives or mechanical fasteners that can compromise the deck's structural integrity. The installation process requires minimal surface preparation beyond basic cleaning and degreasing, making it an attractive option for both new construction and retrofit applications. Professional contractors can complete installations more efficiently, reducing labor costs and project timelines compared to traditional flooring systems.

The modular nature of many EVA foam products allows for easy maintenance and repair, as damaged sections can be replaced individually without disturbing the entire flooring system. This characteristic is particularly valuable for commercial operators who require minimal downtime for maintenance activities. The material's dimensional stability prevents expansion and contraction issues that commonly affect other flooring types in marine environments, ensuring long-term aesthetic appeal and functional performance. Proper edge sealing techniques further enhance the system's water resistance and prevent debris accumulation in joints.

Synthetic Teak Decking Systems

Material Composition and Benefits

Synthetic teak represents a significant advancement in marine decking technology, combining the aesthetic appeal of natural teak with enhanced durability and reduced maintenance requirements. These products typically utilize high-density polyethylene or other engineered polymers that resist fading, cracking, and warping under extreme marine conditions. The manufacturing process incorporates UV stabilizers and marine-grade colorants that maintain appearance integrity for decades, eliminating the need for regular refinishing that characterizes natural wood decking. Synthetic teak systems offer consistent color and texture throughout the product thickness, ensuring that minor surface damage remains virtually invisible.

The non-slip surface texture of quality synthetic teak products provides excellent traction in both dry and wet conditions, exceeding the performance of many natural alternatives. These materials resist staining from fuel, oil, and other marine fluids that commonly encounter deck surfaces during normal vessel operations. The dimensional stability of synthetic materials prevents the expansion and contraction cycles that create gaps and irregularities in traditional wood decking, maintaining a professional appearance throughout the vessel's service life. Additionally, synthetic teak's resistance to marine borers and other wood-destroying organisms eliminates a significant maintenance concern for boat owners.

Long-Term Performance and Maintenance

Synthetic teak decking systems demonstrate exceptional longevity in marine applications, with many manufacturers offering warranties extending 15-25 years for their premium products. The material's resistance to UV degradation, salt corrosion, and temperature cycling ensures consistent performance across diverse operating environments, from tropical waters to harsh northern climates. Regular maintenance consists primarily of basic cleaning with marine-approved detergents, eliminating the need for periodic sanding, sealing, or refinishing required by natural wood alternatives. This reduced maintenance burden translates to significant cost savings over the vessel's operational lifetime.

The inherent stability of synthetic materials prevents the checking, splitting, and splintering that commonly affect natural teak decking as it ages. This characteristic not only maintains aesthetic appeal but also eliminates safety hazards associated with deteriorating wood surfaces. Professional installation techniques ensure proper drainage and ventilation beneath synthetic teak systems, preventing moisture accumulation that could compromise the underlying deck structure. The material's compatibility with standard marine hardware and installation methods facilitates integration with existing vessel systems and accessories.

Composite Decking Materials

Wood-Polymer Composite Advantages

Wood-polymer composite materials have gained popularity in marine applications due to their balanced combination of natural aesthetics and engineered performance characteristics. These products typically incorporate recycled wood fibers with various polymer binders, creating a material that resembles natural wood while offering enhanced durability and reduced maintenance requirements. The manufacturing process allows for precise control of material properties, including density, flexibility, and surface texture, enabling optimization for specific marine applications. Composite materials resist moisture absorption more effectively than natural wood, reducing the risk of rot, decay, and dimensional instability that plague traditional decking systems.

The cellular structure of many composite products provides improved insulation properties compared to solid materials, helping to reduce heat transfer from sun-heated decks to interior spaces. This thermal performance benefit is particularly valuable in warm climate applications where deck surface temperatures can become uncomfortable for barefoot use. Advanced composite formulations incorporate antimicrobial additives that prevent mold and mildew growth, maintaining a clean and healthy deck environment. The material's compatibility with standard woodworking tools and techniques simplifies installation and modification processes for marine contractors familiar with traditional construction methods.

Durability and Weather Resistance

High-quality composite decking materials demonstrate exceptional resistance to the environmental stresses encountered in marine applications, including UV exposure, salt spray, and temperature cycling. The polymer matrix protects embedded wood fibers from moisture absorption and biological attack, significantly extending service life compared to natural wood products. Advanced UV stabilization systems prevent color fading and surface degradation even under intense sunlight exposure common in marine environments. The material's resistance to scratching and surface damage maintains appearance integrity despite heavy foot traffic and equipment movement typical aboard working vessels.

Composite materials exhibit minimal expansion and contraction coefficients, reducing the gap formation and surface irregularities that develop in natural wood decking over time. This dimensional stability ensures consistent appearance and performance throughout seasonal temperature variations and operational conditions. The non-porous surface of quality composite products resists staining from fuel, oil, and other marine fluids, maintaining a clean professional appearance with minimal maintenance effort. Proper installation techniques that account for thermal movement and drainage requirements ensure optimal long-term performance of custom boat flooring systems.

Specialized Marine Vinyl Systems

Material Technology and Applications

Marine-grade vinyl flooring systems represent a versatile solution for vessel applications requiring easy cleaning, chemical resistance, and design flexibility. These products utilize advanced polymer formulations specifically engineered for marine environments, incorporating UV stabilizers, antimicrobial agents, and enhanced tear resistance properties. The manufacturing process allows for virtually unlimited color and pattern options, enabling custom boat flooring designs that complement specific vessel aesthetics and branding requirements. Modern marine vinyl systems feature textured surfaces that provide excellent slip resistance while maintaining easy cleaning characteristics essential for commercial applications.

The waterproof nature of vinyl systems makes them particularly suitable for areas prone to frequent water exposure, including galley spaces, heads, and working deck areas. Advanced backing systems provide cushioning and insulation properties while maintaining dimensional stability under varying temperature and moisture conditions. The material's resistance to common marine chemicals, including cleaning products, fuel, and hydraulic fluids, ensures long-term appearance and performance integrity. Installation systems typically incorporate welded seams that eliminate water penetration points, creating a completely sealed deck surface.

Performance in Marine Environments

Marine vinyl systems demonstrate excellent performance characteristics in harsh saltwater environments, resisting fading, cracking, and degradation from UV exposure and chemical contact. The material's flexibility accommodates the natural flexing and movement of vessel hulls without developing stress cracks or bond failures that compromise system integrity. Quality marine vinyl products maintain their slip-resistant properties throughout their service life, ensuring consistent safety performance even after years of exposure to marine conditions. The material's resistance to bacterial and fungal growth prevents the development of odors and staining that commonly affect other flooring types in marine applications.

Temperature resistance characteristics of marine vinyl allow for installation and operation across a wide range of climatic conditions without performance degradation. The material's low maintenance requirements make it particularly attractive for commercial operators who require reliable performance with minimal upkeep costs. Professional installation techniques ensure proper substrate preparation and adhesion, preventing edge lifting and water intrusion that could compromise system performance. The ability to repair or replace individual sections without disturbing adjacent areas provides operational flexibility for vessel maintenance programs.

Natural Teak and Hardwood Options

Traditional Material Properties

Natural teak remains the gold standard for marine decking applications due to its exceptional natural properties that make it ideally suited for marine environments. The wood's high natural oil content provides inherent water resistance and prevents rapid deterioration from moisture exposure. Teak's tight grain structure and natural density create excellent dimensional stability, reducing warping and checking compared to other hardwood species. The material's natural slip resistance, even when wet, has made it the preferred choice for yacht decking and other high-end marine applications for centuries.

The aesthetic appeal of natural teak is unmatched, developing a beautiful silver-gray patina when exposed to weather conditions, or maintaining its golden color when properly maintained with marine oils and sealers. The material's workability allows for complex joinery and detailed installation work that creates distinctive custom boat flooring systems. Natural teak's compatibility with traditional marine hardware and fastening systems simplifies integration with existing vessel components. However, environmental concerns regarding teak harvesting have led to increased interest in certified sustainable sources and alternative materials that provide similar performance characteristics.

Maintenance Requirements and Longevity

Natural teak decking requires regular maintenance to preserve its appearance and performance characteristics, including periodic cleaning, sanding, and application of protective treatments. Properly maintained teak systems can provide decades of service, making them cost-effective despite higher initial investment costs compared to synthetic alternatives. The maintenance process requires specialized knowledge and materials to avoid damage to the wood's natural properties and appearance. Professional maintenance programs ensure optimal performance and appearance retention throughout the material's service life.

The natural aging process of teak creates unique character and beauty that many vessel owners prefer over synthetic alternatives. However, inconsistent maintenance can lead to accelerated deterioration, including surface checking, joint separation, and structural weakening that compromises both appearance and safety. Modern teak installation techniques incorporate improved fastening systems and substrate preparation methods that enhance longevity and reduce maintenance requirements. The investment in natural teak decking often provides excellent return value for high-end vessels where aesthetic appeal and traditional craftsmanship are priorities.

FAQ

What factors should be considered when selecting custom boat flooring materials?

Key factors include environmental resistance to UV, saltwater, and temperature extremes, slip resistance for safety, ease of maintenance and cleaning, aesthetic compatibility with vessel design, installation requirements and costs, long-term durability expectations, and budget constraints. Material selection should also consider the specific use areas aboard the vessel, with high-traffic zones requiring more durable solutions than occasional-use spaces.

How does EVA foam compare to traditional marine flooring materials in terms of performance?

EVA foam offers superior water resistance, easier installation, lower maintenance requirements, and better cushioning properties compared to traditional materials like natural teak or composite decking. While it may not provide the same aesthetic appeal as natural wood, EVA foam excels in practical performance metrics including durability, safety, and cost-effectiveness over the long term.

What maintenance is required for synthetic marine flooring systems?

Synthetic marine flooring typically requires only regular cleaning with approved marine detergents and periodic inspection for damage or wear. Unlike natural materials, synthetic systems generally do not require refinishing, sealing, or extensive restoration work, making them attractive for vessel owners seeking low-maintenance solutions without compromising performance or appearance.

Can custom boat flooring be installed over existing deck surfaces?

Many custom boat flooring systems can be installed over existing surfaces provided the substrate is structurally sound, clean, and properly prepared. However, specific installation requirements vary by material type and manufacturer specifications. Professional assessment of existing deck conditions is recommended to ensure proper adhesion and long-term performance of the new flooring system.

Table of Contents

- Marine-Grade EVA Foam Flooring Solutions

- Synthetic Teak Decking Systems

- Composite Decking Materials

- Specialized Marine Vinyl Systems

- Natural Teak and Hardwood Options

-

FAQ

- What factors should be considered when selecting custom boat flooring materials?

- How does EVA foam compare to traditional marine flooring materials in terms of performance?

- What maintenance is required for synthetic marine flooring systems?

- Can custom boat flooring be installed over existing deck surfaces?