fabricant de pads d'adhérence de surfboard

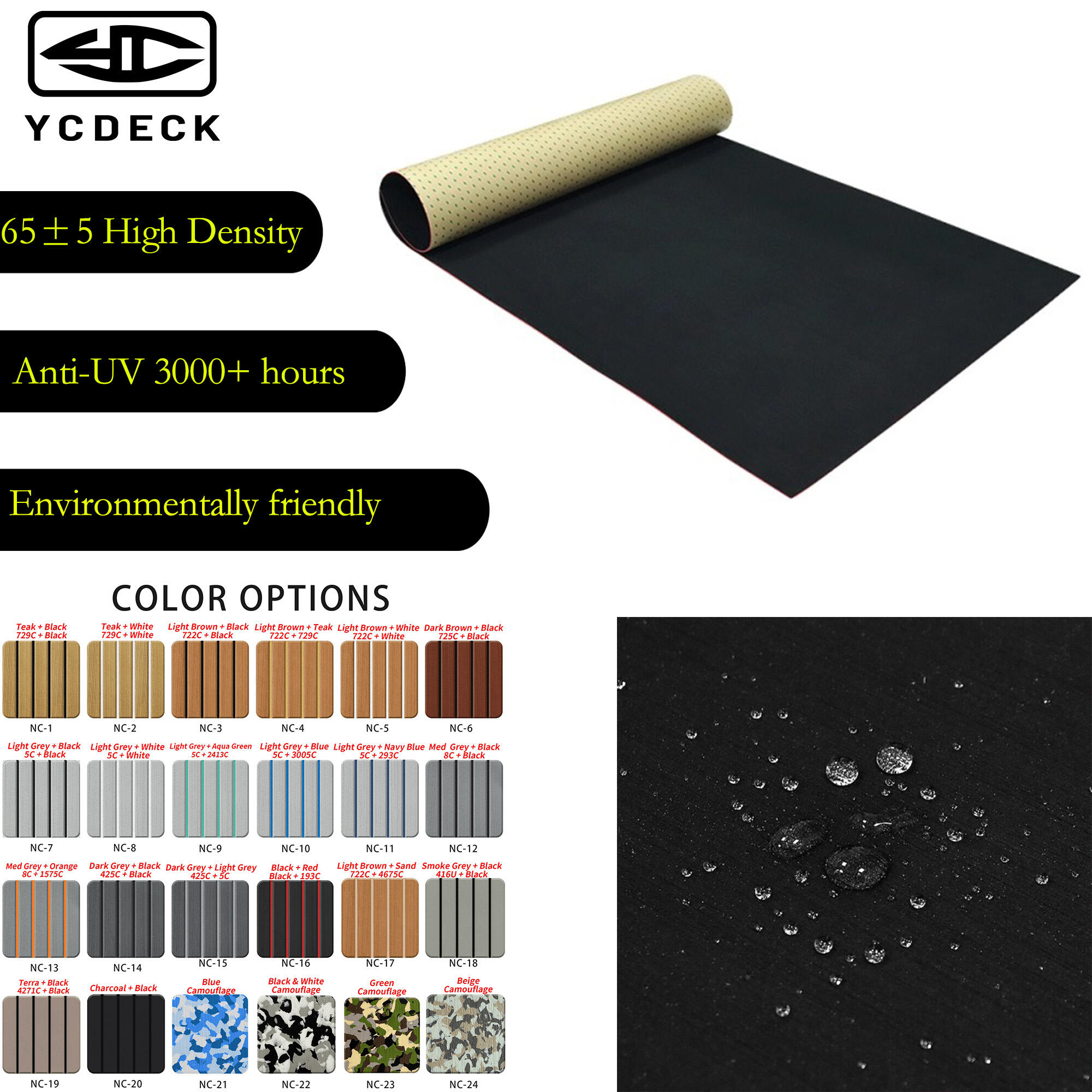

Un fabricant de pads d'adhérence pour surfboards se spécialise dans la production de solutions de grip de haute qualité et durables pour les planches de surf, combinant des matériaux innovants et des processus de fabrication précis. Ces fabricants utilisent des technologies polymères avancées et des techniques de moulage spécialisées pour créer des pads d'adhérence qui améliorent les performances des surfeurs et le contrôle de la planche. Le processus de fabrication implique une sélection soigneuse des matériaux, y compris des mousses EVA de haute qualité et des adhésifs marins, garantissant des produits résistant aux conditions océaniques sévères. Les installations modernes emploient des conceptions assistées par ordinateur et des systèmes de découpe automatisés pour maintenir une qualité constante et des spécifications précises. La chaîne de production intègre des mesures rigoureuses de contrôle qualité, testant chaque pad pour sa durabilité, son efficacité d'adhérence et sa force d'adhésion. Ces fabricants collaborent souvent avec des surfeurs professionnels et des experts en sports nautiques pour développer des produits répondant aux exigences de performance du monde réel. Les installations sont équipées d'équipements de thermoformage de pointe et de machines de découpe sur mesure, permettant la création de divers designs et motifs de pads. Des considérations environnementales sont intégrées dans le processus de fabrication, avec de nombreuses installations mettant en œuvre des pratiques durables et utilisant des matériaux écologiques lorsque cela est possible.