Wprowadzenie do materiałów piankowych

Materiał piankowy ma coraz większe znaczenie w współczesnej technologii, ponieważ znaleziono dla niego tak wiele zastosowań. Są wszechobecne w tak różnych sektorach jak motoryzacja, opakowania, izolacja i dobra konsumpcyjne zmieniają sposób, w jaki pRODUKTY są zaprojektowane i stosowane. Ich niska waga i wysoka trwałość przyczyniają się do efektywnego wykorzystania energii, co zmniejsza emisję gazów cieplarnianych i oszczędza koszty transportu. W sensie logistycznym tylko to sprawia, że materiały piankowe są niezbędne, ponieważ umożliwiają bezpieczną i opłacalną wysyłkę produktu.

Więcej niż tylko dla oszczędności, materiały piankowe są popularne dzięki swojemu wyjątkowemu amortyzowaniu. Ofiarowują one ostateczną ochronę i wygodę dla produktów w przemyśle, takim jak artykuł sportowy i meble. Niezależnie od tego, czy są projektowane do produkcji wygodnych siedzeń czy wyposażenia ofensywnego dla sportowców, nie ma im równych pod względem elastyczności. To znacznie więcej niż po prostu maca antykolizyjna – nie tylko absorbuje uderzenia, oferując miękkie miejsce do lądowania, ale również zapewnia poważne zadowolenie użytkownika, tworząc bezpieczne środowisko dotykowe, praktycznie wszędzie, gdzie bezpieczeństwo i wygodność idą ręk w rękę. Pianka – możliwości są nieograniczone. Dzięki głębokiemu zrozumieniu naturalnych właściwości pianki, różne branże mogą manipulować materiałami piankowymi na nowe i bardziej efektywne sposoby.

Co to jest pianka EVA?

Skład chemiczny etylenu i winilowej kwasu octowego

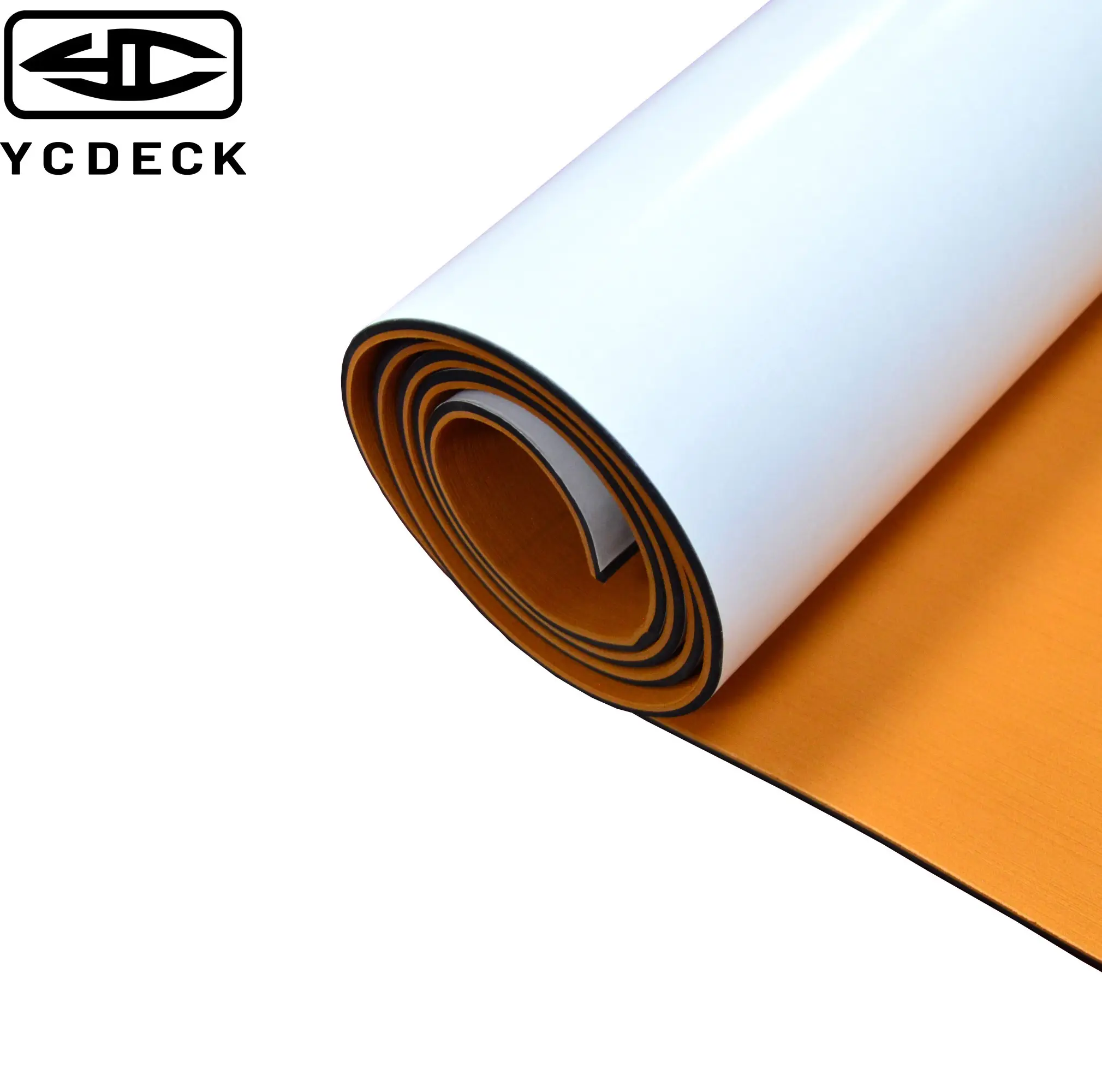

Piana EVA (etilen-winylacetat) to kopolimer etylenu i winylacetatu, zawartość winylacetatu waha się od 10 do 90%. Ta charakterystyczna struktura chemiczna odpowiada za doskonałe właściwości sprężyste i optyczne materiału; im wyższa zawartość VAc, tym materiał jest mińszy i bardziej sprężysty, co sprawia, że jest idealny do różnych zastosowań. Wiedza na temat chemii związanej z EVA jest kluczowa podczas określania odpowiednich zastosowań końcowych i warunków przetwarzania, ponieważ te informacje pozwalają producentom dostosowywać wydajność materiału do wymagań danego zastosowania.

Podstawowe właściwości fizyczne pianki EVA

Pianka Soft Flex® EVA jest nieporównywalnie lekka i elastyczna, dlatego jest głównie stosowana w zabezpieczeniach amortyzacyjnych oraz jako wypełnienie do walizek. Dzięki doskonałej odporności na uderzenia pianka EVA stanowi idealny materiał do produkcji sprzętu sportowego i obuwia ochronnego przeznaczonego na ekstremalne warunki. Oprócz możliwości gięcia, EVA charakteryzuje się również doskonałą odpornością na promieniowanie UV i warunki atmosferyczne – może być stosowana w aplikacjach zewnętrznych bez ryzyka osłabienia pod wpływem czynników środowiskowych, jak to ma miejsce przy gorszych materiałach. Dodatkowo EVA jest nietoksyczna i stanowi niezwykle uniwersalny materiał, a wiele odmian gęstości i twardości sprawia, że nadaje się ona do szerokiego zakresu zastosowań przemysłowych i konsumenckich.

Typowe zastosowania przemysłowe i konsumenckie

Szczeka zastosowań pianki EVA nie może zostać przeceniona. W produkcji obuwia oferuje ona bezprecedensowe miękkość i amortyzację, które są podstawowymi elementami w butach sportowych i codziennych. Pianka EVA jest również szeroko stosowana jako wyściółka piankowa w przemyśle samochodowym, między wyściółką pojazdu, siedzeniami lub w tablicy rozdzielczej, aby poprawić izolację dźwiękową, elektryczną oraz spójność pianki. Jej zastosowanie w codziennych produktach jest powszechne, od mat do jogi po zabawki dla dzieci, które korzystają z jej bezpieczeństwa w użyciu i amortyzacji. Pielęgnicze zastosowanie pianki EVA może być wykorzystywane w różnych celach, w tym: konstrukcji puzzle'ów, DIY podłogi deskami/poduszkami/kostiumami/cosplayami, ochrona pokojów dziecięcych i sal gier, wyściółka zabawek i gier, a także może być stosowana jako rozwiązanie izolacji dźwiękowej ścian lub sufitów.

Rozumienie zwykłej pianki

Rodzaje zwykłej pianki: poliuretan vs. polietilen

Powszechna piana dzieli się przede wszystkim na dwa rodzaje: poliuretanową i polietylową. Piana poliuretanowa ceni się za swoją elastyczność i jest szeroko wykorzystywana do poduszek, materaców oraz izolacji. Z drugiej strony, piana polietylowa oferuje większą twardość i sprężystość, dlatego znajduje zastosowanie w pakowaniu i innych przypadkach transportowych, zapewniając doskonałe tłumienie wstrząsów. Metody produkcji tych pian różnią się znacznie pod względem kosztów i wpływu na środowisko. Procesy przygotowywania poliuretanu są bardziej skomplikowane niż w przypadku polietylenu. Podczas podejmowania decyzji między tymi dwoma rodzajami pian należy uwzględnić ich różne zastosowania: poliuretan w siedzeniach dla komfortu, a polietylen w obsadach i bezpieczeństwie.

Strukturalne cechy i ograniczenia

Typowe pianki mają różne gęstości i struktury, które wpływają na ich zastosowanie i żywotność. Ogólnie można je sklasyfikować jako struktury o komórkach otwartych i zamkniętych, każda z własnymi charakterystycznymi cechami. Pianki o komórkach otwartych są mińsze i bardziej oddechowe, ale mniej sprężyste i mają wyższą przepuszczalność powietrza. W przeciwieństwie do nich, pianki o komórkach zamkniętych oferują lepszą odporność na wilgoć i większą sztywność, ale są bardziej sztywne i mniej wygodne. Znajomość tych różnic jest ważna przy wybieraniu pianki do konkretnego zastosowania, aby uniknąć ograniczeń właściwości takich jak stopień spłaszczenia lub degradacji. Wiedza, czy pianka będzie używana w środowisku wilgotnym czy jako podkładka do oparcia, może pomóc Ci zdecydować, który typ wybrać.

Typowe zastosowania w życiu codziennym

Wszyscy znamy „zwykłe” pianki, takie jak te używane w poduszkach siedzeniowych i materacach oraz jako materiały izolacyjne w chłodnictwie i dźwiękoszczędności. Ich przystosowalność sprawia, że mogą być stosowane w wielu produktach o różnych potrzebach funkcyjnych. Ponadto rosnący nacisk na ekologiczne pianki wpływa na ich zastosowania i popycha je w kierunku nowych rozwiązań w projektowaniu zrównoważonym. Ich uniwersalność jest nieoceniona w szerokim zakresie zastosowań, od mebli po opakowania. Postępy w przetwarzaniu materiałów umożliwiły zaprojektowanie niektórych pianek z uwzględnieniem zrównoważonego rozwijania środowiska, otwierając ich zastosowanie w szerokim zakresie codziennego życia.

Głównicze Różnice Między Pianką EVA a Zwykłą Pianką

Porównanie Gęstości i Wagi

Piana EVA jest zazwyczaj lżejsza i mniej gęsta niż zwykła piana, co czyni ją idealnym materiałem do absorpcji szoków lub ochrony ciała. Ta mniejsza gęstość odpowiada za oszczędność wagi obserwowaną w produkach konsumenckich, takich jak sprzęt sportowy i produkty amortyzujące. Gęstość piany wpływa na wydajność, dlatego ważne jest to zrozumienie, ponieważ wpływa na rzeczy takie jak trwałość i stopień amortyzacji buta. Kwantyfikacja tej różnicy w gęstości umożliwia podejmowanie bardziej inteligentnych decyzji w zakresie projektowania produktów i logistyki, zwłaszcza w obszarze technik konstrukcji lekkich.

Pliwotliwość i zdolności absorpcji szoków

Piana EVA jest bardziej wydajna niż tradycyjne piany polipropylenu lub poliuretanu w pochłanianiu szoku oraz podczas zginania piany, oferując jednocześnie elastyczność w szerokim zakresie temperatur. Jego giętki charakter jest szczególnie pożądany, a także stosowany w aktywnościach sportowych, gdzie naturalne ruchy są kluczowe. Większe pochłanianie szoku dzięki pianie EVA zostało potwierdzone przez badania porównawcze [pokazujące jej wydajność w sytuacjach o wysokim impakcie]. To czyni EVA pożądaną opcją dla produktów, które wymagają trwałe ochrony.

Trwałość i odporność na warunki środowiskowe

Piana EVA ceni się również za swoją wysoką oporność na czynniki środowiskowe, w tym promieniowanie ultrafioletowe i wilgoć. Ta cecha sprawia, że jest to produkt trwały i znacznie bardziej długowieczny niż zwykła piana. Badania wykazały, że trwała natura EVA prowadzi do obniżonych kosztów przez całe życie produktu, ponieważ produkty nie muszą być zamieniane tak często. Te aspekty trwałości czynią z piany EVA materiał wyjątkowo wytrzymały i ulubiony wybór dla zastosowań o wysokim narażeniu, takich jak meble ogrodowe, gdzie oporność na elementy środowiskowe jest kluczowa.

Analiza kosztów i wariacje produkcji

Wybór między pianką EVA a zwykłą pianką często zależy od kosztów i procesów produkcyjnych, które różnią się znacznie między rodzajami pianek. Pianki EVA są zazwyczaju droższe do wyprodukowania, ale mogą się okazać wartymi inwestycji, ponieważ są bardziej trwałe i oferują lepsze wsparcie. Weźcie pod uwagę stosunek kosztów w czasie do czasu życia produktów, co może pomóc w dokonaniu bardziej strategicznych inwestycji w materiały piankowe. Na początku mogą się wydawać droższe, ale długoterminowe korzyści oraz mniejsza częstotliwość wymiany zapewniają efektywność kosztową na dłuższą metę.

Wybór odpowiedniej pianki dla Twojego projektu

Dopasowywanie właściwości pianek do potrzeb aplikacji

Wybór odpowiedniego pianka dla danego zadania jestważny, ponieważ określa, czy będzie w stanie spełnić czynniki określone dla danej aplikacji, takie jak gęstość, giętkość i odporność na wilgoć. Każda aplikacja jest unikalna; pianki o wysokiej gęstości mogą na przykład być preferowane w przypadku wsparcia strukturalnego, podczas gdy pianki o niskiej gęstości mogą lepiej nadawać się do amortyzacji. Rozmowa z specjalistami od materiałów może pomóc uzyskać wiele wglądu w kwestię, który rodzaj pianki byłby najlepszy w konkretnej sytuacji i aplikacji. Mogą również służyć do porównywania materiałów, pomagając decydentom wybrać optymalne rozwiązania piankowe dla ich aplikacji, które są zoptymalizowane pod kątem zarówno wydajności, jak i kosztów.

Zważycie kosztów i korzyści w przypadku długoterminowego stosowania

Zaoszczędzone koszty konserwacji są ogromne, jeśli uwzględni się koszty długoterminowe w porównaniu do początkowych kosztów pianki. Ta ocena powinna uwzględniać częstotliwość potencjalnej wymiany, konserwacji oraz konsekwencje ekologiczne. Niektóre z tych drogich materiałów piankowych mogą okazać się opłacalne na dłuższą metę dzięki zwiększonej sile i lepszej wydajności. Według niektórych studiów przypadku wybór odpowiedniej pianki może przedłużyć żywotność produktu i obniżyć koszty, podkreślając potrzebę rozważenia korzyści długoterminowych.

Sekcja FAQ

Jakie są główne branże wykorzystujące materiały piankowe?

Materiały piankowe są szeroko stosowane w branżach takich jak motoryzacyjna, opakowania, izolacja, produkty konsumentów, artykuły sportowe i meble ze względu na ich lekkość, odporność i właściwości amortyzujące.

Jaka jest składnia chemiczna pianki EVA?

Piana EVA to kopolimer zbudowany z etylenu i kwasu winilowego. Udział kwasu winilowego zwykle wynosi od 10% do 90%, co wpływa na jego sprężystość i przejrzystość.

W jaki sposób piana EVA różni się w giętkości w porównaniu z zwykłą pianą?

Piana EVA ogólnie oferuje większą giętkość i pochłanianie szoków w porównaniu z zwykłą pianą poliuretanową, co czyni ją idealną do zastosowań ochronnych, zwłaszcza w sporcie i innych dynamicznych środowiskach.

Jakie są typowe zastosowania piany polietilenowej?

Piana polietilenowa jest powszechnie stosowana w pakowaniu i przewozie ze względu na jej wybitne właściwości amortyzujące i często wybierana jest za jej sztywność i odporność.