Introduction to Foam Materials

Foam material has increasing importance in contemporary technology since so many applications for it have been found. They are omnipresent in sectors as diverse as automotive, packaging, insulation and consumer goods – changing the way products are designed and used. Their low-weight and high-durability contribute to an efficient use of energy, which reduces the emission of greenhouse gases and saves costs for transportation. Logistically this alone makes foam materials imperative as it permits safe, cost-effective shipment of product.

More than just for its economical savings, foam materials are popular for their superior cushioning. They offer the ultimate protection and comfort for products in industries like sporting goods and furniture. Regardless if designed for producing cozy seats or offensive equipment for sportsmen, they can't be surpassed in the flexibility. It’s so much more than basically just a crash mat – they not only absorb impact, providing a soft place to touch down, but also provide serious user enjoyment, providing a touch safe environment, practically anywhere, where safety and comfort go hand in hand. Foam – the Possibilities are Endless With a deep understanding of foam’s inherent characteristics, various industries are able to manipulate foam materials in new and more effective ways.

What is EVA Foam?

Chemical Composition of Ethylene-Vinyl Acetate

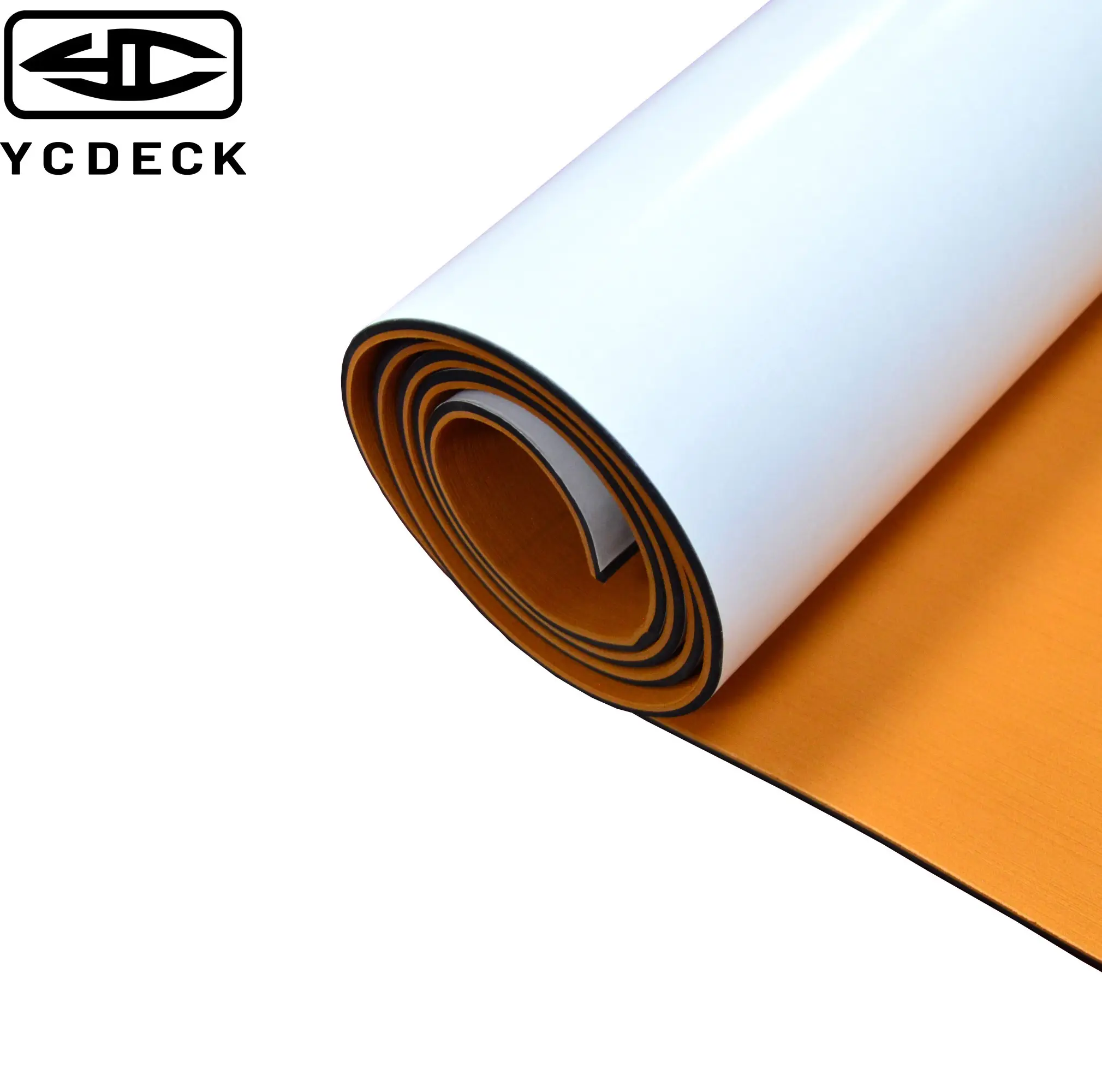

EVA (ethylene–vinyl acetate) foam is a copolymer of ethylene and vinyl acetate, vinyl acetate content varies from 10 to 90%. This distinctive chemical structure is responsible for the material's excellent elastic and optical nature; the higher the va the softer and more elastic the material is, which make it ideal for a variety of different applications. Knowledge of the chemistry involved with EVA is imperative when determining appropriate end-uses and processing conditions, as this information enables manufacturers to customize the performance of the material to meet the specifications of an application.

Key Physical Properties of EVA Foam

Soft Flex® EVA foam is incomparably light and flexible, which is why it is mainly used in padded protection and in padding for cases. Due to its excellent impact resistance, EVA foam is an ideal material for making extreme sports gear and protective footwear. In addition to being able to flex, EVA also has excellent UV and weather resistance properties - it can be used in outdoor applications without being weakened from environmental exposure, like with inferior materials. Furthermore, EVA is nontoxic and is an extremely versatile material, with numerous varieties of density and hardness making it suitable for a vast range of industrial and consumer applications.

Common Industrial and Consumer Uses

The wide range of applications for EVA foam cannot be underestimated. In shoe making, it offers unsurpassed softness and cushioning, which are cornerstone elements in sports and casual shoes. EVA foam is also widely used as foam padding in the automotive industry, between vehicle lining, seating or in the instrument panel, to promote soundproofing, electrical resistance, and the foam cohesiveness. It’s use in everyday products is extensive, from yoga mats to children’s toys that have benefitted from it’s safe to use, cushioning nature. Versatile usage EVA foam can be used in various applications including:construction of jigsaw puzzles, DIY floor board/pillows/costumes/cosplays, children's rooms and playrooms protection, toy and games padding, also can be used as soundproofing wall or ceiling solution.

Understanding Regular Foam

Types of Regular Foam: Polyurethane vs. Polyethylene

General foam is mainly divided into two types polyurethane and polyethylene. Polyurethane foam is valued for its flexibility and is used extensively for cushions, mattresses, and insulation. In the other hand, Polyethylene foam gives more firmness and elasticity, therefore it is widely used in packaging and other shipping cases to provide outstanding shock absorption. The production methods for these foams differ considerably in their cost and environmental impact. Processes for preparing polyurethane are more complicated than polyethylene. When making the decision between these two types of foam, their disparate uses are considered: polyurethane in seating for comfort, while polyethylene in support and security.

Structural Characteristics and Limitations

Typical foams have different densities and various structures which affect their use and life. They can be generally classified as opened-cell and closed-cell structures with their distinctive features. Open-cell foams are softer and more breathable, but not as resilient and have higher air permeability. In contrast, closed-cell foams offer superior moisture resistance and rigidity, but tend to be more rigid and less comfortable. Knowledge of these differences is important in choosing a foam for a particular application to avoid restricting properties such as compression set or degradation. Knowing if foam will be used in a wet environment or a cushion to lean against, can help you decide which type to use.

Typical Applications in Daily Life

We are all familiar with “ordinary” foams, such as those used in seat cushions and mattresses, and as insulating materials in refrigeration and sound-proofing. Their adaptability makes them applicable in multiple products with different functional needs. Furthermore, the growing focus on environmentally friendly foams is influencing their uses and driving them to new ways in sustainable design. Their versatility is indispensable for a wide range of applications, from furniture to packaging. Advancements in material processing have allowed for some foams to be designed with an aim toward environmental sustainability, opening their use to a range of applications in everyday life.

Key Differences Between EVA and Regular Foam

Density and Weight Comparison

EVA foam is often lighter and less dense than regular foam, making it an ideal material for shock absorption or body protection. This lower density is responsible for the weight savings observed in consumer goods, such as sports equipment and cushioning products. Foam density effects performance and it's important to know how because it affects things like durability and how cushioned a shoe is. A quantification of this density difference allows for more intelligent choices of product design and logistics decisions, especially in the area of lightweight construction techniques.

Flexibility and Shock Absorption Capabilities

EVA foam is more efficient than traditional popylene or polyurethane foams at being able to tansorb shock and also throughout the folding of the foam while offering flexibility over a wide range of temperatures. Its pliable character is particularly desirable, also used in sports activities where natural motions are critical. Higher shock absorption due to EVA foam is substantiated by comparative researches [showing its efficiency on high-impact instances]. This makes EVA a desirable option for items that require durable protection.

Durability and Environmental Resistance

EVA foam is also prized for it's highly resistant to those environmental concerns, including ultraviolet light and moisture. This feature turns it into a long lasting product and is much more long lasting than your average foam. Studies have shown that the enduring nature of EVA leads to reduced lifetime costs, products don’t need to be replaced as often. These durability aspects make EVA foam a highly durable material and a favorite choice for high exposure applications such as outdoor furniture where resistance to environmental elements is considered.

Cost Analysis and Production Variations

The choice between EVA and regular foam often depends on production costs and processes, which differ greatly between foam types. EVA foams tend to be more expensive to produce, but may be worth the investment, as they tend to be more durable and supportive. Taking the cost over time versus the lifespan of the products can help guide you toward more strategic investments in foam materials. They can be perceived initially as more expensive but the long term benefits and less replacement frequency offer value in long term cost effectiveness.

Choosing the Right Foam for Your Project

Matching Foam Properties to Application Needs

Picking the proper foam for a job is important because it determines whether it is able to meet factors specific to an application, such as density, flexibility, and moisture resistance. Each application is unique; high-density foams may, for example, be desired for structural support, while low-density foams can be better for cushioning. Talking with material specialists can help gain a great deal of insight about which type of foam would be best for specific situations and applications. They also can be used to compare materials helping decision-makers pick the optimal foam solutions for their applications that are optimized to take both performance and cost effectiveness into consideration.

Cost-Benefit Considerations for Long-Term Use

The savings on maintenance are enormous if you factor in long-term costs compared to the initial cost of foam. This evaluation should take into account the frequency of potential replacement, maintenance, and ecological consequences. Some of these expensive foam materials can pay for themselves in the long run with added strength and better performance. According to some case studies, choosing the right foam can prolong the life of a product and reduce costs, emphasizing the need to consider long-term benefits.

FAQ Section

What are the main industries that utilize foam materials?

Foam materials are extensively used in industries such as automotive, packaging, insulation, consumer goods, sporting goods, and furniture due to their lightweight, resilient, and cushioning properties.

What is the chemical composition of EVA foam?

EVA foam is a copolymer made from ethylene and vinyl acetate. The proportion of vinyl acetate typically ranges from 10% to 90%, influencing its elasticity and clarity.

How does EVA foam differ in flexibility compared to regular foam?

EVA foam generally offers greater flexibility and shock absorption compared to regular polyurethane foam, making it ideal for protective applications, especially in sports and other dynamic environments.

What are typical applications for polyethylene foam?

Polyethylene foam is commonly used in packaging and shipping for its superior shock absorption and is often chosen for its rigidity and resilience.