Brushed eva foam sheets have become increasingly popular in marine, automotive, and industrial applications due to their exceptional durability, non-slip properties, and aesthetic appeal. These specialized foam materials require proper maintenance and cleaning techniques to preserve their functionality and extend their service life. Understanding the unique characteristics of brushed eva foam sheets is essential for implementing effective care routines that maintain their surface texture, adhesive properties, and overall performance in demanding environments.

The brushed texture surface of these foam sheets creates a unique pattern that not only enhances grip but also requires specific cleaning approaches to prevent damage to the delicate surface fibers. Professional maintenance of brushed eva foam sheets involves understanding the material composition, environmental factors that affect longevity, and appropriate cleaning agents that won't compromise the foam's integrity or adhesive backing.

Understanding the Material Properties of Brushed Eva Foam

Composition and Structure Analysis

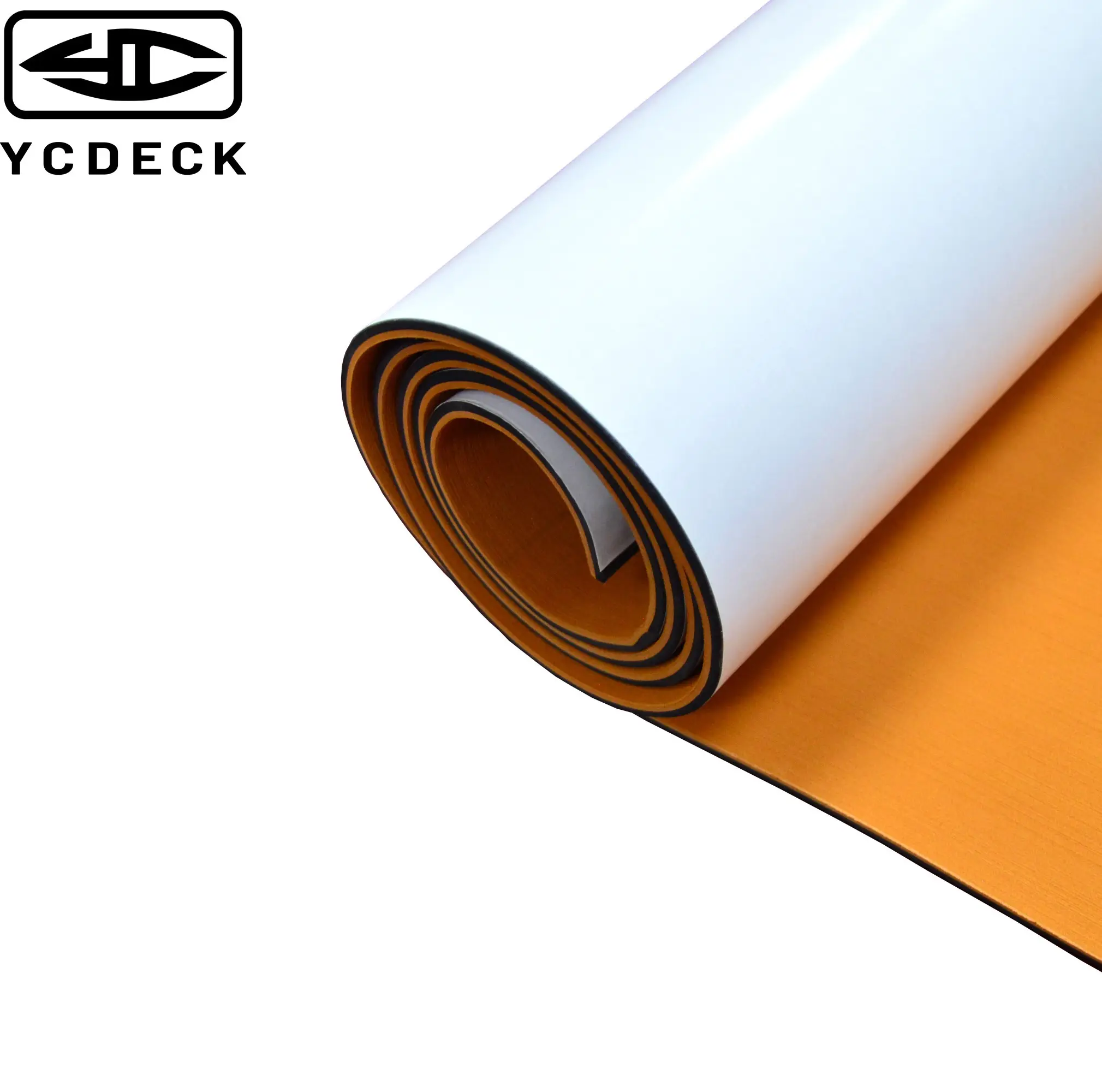

Ethylene-vinyl acetate copolymer forms the foundation of brushed eva foam sheets, providing excellent flexibility, chemical resistance, and UV stability. The brushed surface treatment creates microscopic fibers that increase surface area and enhance grip characteristics. This specialized texture requires careful handling during cleaning to prevent fiber damage or flattening that could reduce the material's effectiveness.

The cellular structure of eva foam allows for excellent shock absorption and water resistance, making it ideal for marine deck applications. However, this same porosity can trap contaminants if not properly maintained. Understanding these structural properties helps determine appropriate cleaning frequencies and methods that preserve the material's performance characteristics while removing accumulated debris and contaminants.

Surface Texture Characteristics

The brushed finish on eva foam sheets creates directional fibers that provide enhanced traction and visual appeal. These surface fibers are designed to withstand normal wear but can be damaged by aggressive cleaning methods or harsh chemicals. Proper maintenance techniques must account for fiber orientation and density to ensure cleaning effectiveness without compromising the textured surface.

Temperature variations, UV exposure, and mechanical stress can affect the brushed texture over time. Regular inspection of the surface condition helps identify areas requiring special attention during cleaning routines. Maintaining the integrity of the brushed texture directly impacts the material's slip resistance and aesthetic qualities, making proper care essential for optimal performance.

Preparation Techniques for Effective Cleaning

Initial Assessment and Surface Inspection

Before beginning any cleaning procedure, conduct a thorough visual inspection of the brushed eva foam sheets to identify problem areas, staining patterns, and surface damage. This assessment guides the selection of appropriate cleaning methods and helps prevent unnecessary wear or damage during the maintenance process. Document any existing damage or wear patterns to track the effectiveness of cleaning procedures over time.

Remove loose debris, sand, and surface contaminants using soft-bristled brushes or compressed air before applying any liquid cleaning solutions. This preliminary step prevents abrasive particles from being ground into the foam surface during wet cleaning procedures. Pay particular attention to seams, edges, and areas where the foam meets other materials, as these locations often accumulate more debris.

Tool Selection and Preparation

Select cleaning tools that complement the brushed texture without causing damage to surface fibers. Soft-bristled brushes, microfiber cloths, and non-abrasive sponges provide effective cleaning action while preserving the foam's surface integrity. Avoid steel wool, harsh scrubbing pads, or stiff brushes that can flatten or tear the delicate brushed fibers.

Prepare cleaning solutions using mild detergents specifically formulated for synthetic materials. Test cleaning agents on a small, inconspicuous area before full application to ensure compatibility with the foam material and adhesive backing. Maintain appropriate solution temperatures, typically room temperature to lukewarm, to prevent thermal damage to the foam structure.

Daily Maintenance and Routine Care

Regular Cleaning Schedules

Establish consistent daily maintenance routines that prevent the accumulation of contaminants and extend the service life of brushed eva foam sheets. Daily care typically involves removing surface debris, wiping down high-traffic areas, and addressing spills or stains immediately. These routine maintenance activities require minimal time investment but significantly impact long-term material performance and appearance.

Frequency of cleaning depends on environmental conditions, usage patterns, and exposure to contaminants. Marine environments may require twice-daily cleaning due to salt spray and organic matter accumulation, while indoor applications might need only weekly thorough cleaning with daily spot maintenance. Adjust cleaning schedules based on observed contamination rates and material condition.

Quick Response Procedures

Implement immediate response procedures for spills, stains, and heavy contamination to prevent permanent damage or staining. Quick action prevents liquids from penetrating deeply into the foam structure and reduces the likelihood of permanent discoloration or odor retention. Keep appropriate cleaning supplies readily available for rapid response to contamination incidents.

Blot liquid spills immediately using absorbent cloths, working from the outside of the spill toward the center to prevent spreading. Avoid rubbing or scrubbing during initial spill response, as this can force contaminants deeper into the foam structure. Follow immediate blotting with appropriate cleaning procedures based on the type of contamination encountered.

Deep Cleaning Methodologies

Comprehensive Cleaning Procedures

Deep cleaning of brushed eva foam sheets requires systematic approaches that address embedded contaminants while preserving surface texture and material integrity. Begin with thorough pre-cleaning to remove loose debris, followed by application of appropriate cleaning solutions using gentle scrubbing motions that follow the grain of the brushed texture. This methodical approach ensures complete contamination removal without damaging surface fibers.

Rinse thoroughly with clean water to remove all cleaning residues that could attract future contamination or cause material degradation. Use low-pressure water application to prevent forcing contaminants deeper into the foam structure or damaging the brushed surface texture. Multiple rinse cycles may be necessary for heavily soiled areas or when using concentrated cleaning solutions.

Specialized Treatment Methods

Certain contamination types require specialized treatment approaches that go beyond standard cleaning procedures. Oil-based stains may need degreasing agents applied with extended contact times, while biological contamination might require antimicrobial treatments. Develop specialized protocols for common contamination types encountered in specific applications to ensure effective remediation without material damage.

Steam cleaning can be effective for deep sanitization of brushed eva foam sheets, but requires careful temperature and pressure control to prevent thermal damage or texture distortion. Use appropriate steam cleaning equipment with adjustable settings and test on inconspicuous areas before full application. Follow steam treatment with proper drying procedures to prevent moisture retention and potential mold growth.

Drying and Post-Cleaning Care

Proper Drying Techniques

Effective drying is crucial for preventing moisture-related problems such as mold growth, adhesive failure, or material degradation. Allow brushed eva foam sheets to air dry completely before resuming normal use, ensuring adequate ventilation to facilitate moisture evaporation. Position the material to promote airflow across all surfaces while avoiding direct sunlight that could cause thermal damage or UV degradation.

Use fans or forced air circulation to accelerate drying in humid conditions or confined spaces where natural air circulation is limited. Monitor drying progress regularly and ensure complete moisture removal from the foam structure and underlying adhesive layers. Incomplete drying can lead to adhesive failure, trapped moisture problems, and reduced material performance.

Surface Restoration and Protection

After cleaning and drying, inspect the brushed surface for any fiber flattening or texture distortion that may have occurred during the cleaning process. Gentle brushing with appropriate tools can help restore the surface texture and maintain the material's non-slip properties. Use soft-bristled brushes and work in the direction of the original brush pattern to restore optimal surface characteristics.

Apply protective treatments if recommended by the manufacturer to enhance UV resistance, water repellency, or anti-microbial properties. These treatments can extend service life and reduce future maintenance requirements, but must be compatible with the foam material and existing surface treatments. Test protective products on sample areas before full application to ensure compatibility and effectiveness.

Troubleshooting Common Issues

Stain Removal Strategies

Different types of stains require specific removal approaches to achieve effective results without damaging the brushed eva foam sheets. Protein-based stains respond well to enzymatic cleaners, while mineral deposits may require mild acidic solutions for effective removal. Develop a systematic approach to stain identification and treatment selection based on contamination source and characteristics.

Persistent stains may require multiple treatment cycles with increasing intensity, but always prioritize material preservation over complete stain removal. Some discoloration may be permanent without risking material damage through aggressive treatment methods. Document stain treatment results to refine future cleaning procedures and prevent similar contamination issues.

Surface Damage Prevention

Preventing surface damage during cleaning requires understanding the limitations of the brushed texture and avoiding cleaning methods that exceed these limits. Monitor cleaning tool wear and replace brushes or cleaning implements before they become abrasive enough to damage the foam surface. Regular tool maintenance ensures consistent cleaning effectiveness while protecting material integrity.

Train personnel in proper cleaning techniques and provide clear guidelines for tool selection, solution preparation, and application methods. Consistent application of appropriate cleaning procedures reduces the risk of accidental damage and ensures uniform maintenance quality across all foam installations. Regular training updates help incorporate new techniques and address emerging maintenance challenges.

Long-term Preservation Strategies

Preventive Maintenance Programs

Develop comprehensive preventive maintenance programs that address both routine cleaning requirements and long-term preservation strategies for brushed eva foam sheets. These programs should include regular inspection schedules, cleaning procedure documentation, and performance tracking to optimize maintenance effectiveness. Preventive approaches are more cost-effective than reactive maintenance and help ensure consistent material performance.

Environmental monitoring helps identify conditions that accelerate material degradation or increase maintenance requirements. Temperature fluctuations, humidity levels, UV exposure, and contamination sources all impact maintenance needs and cleaning frequencies. Adjust maintenance programs based on environmental data to optimize resource allocation and material preservation.

Performance Monitoring and Assessment

Regular performance assessment of cleaned brushed eva foam sheets helps evaluate cleaning effectiveness and identify areas for procedure improvement. Monitor surface texture retention, grip characteristics, and overall appearance to ensure maintenance procedures are achieving desired results without causing gradual material degradation. Performance data guides maintenance schedule adjustments and procedure refinements.

Document maintenance activities and results to build a comprehensive database of cleaning effectiveness under various conditions. This information supports troubleshooting efforts, helps predict maintenance requirements, and provides valuable data for optimizing cleaning procedures. Regular analysis of maintenance records identifies trends and opportunities for improvement in care routines.

FAQ

How often should brushed eva foam sheets be cleaned in marine environments

Marine environments typically require daily surface cleaning due to salt spray, organic matter, and high moisture conditions. Comprehensive deep cleaning should be performed weekly or bi-weekly depending on usage intensity and contamination levels. Salt water exposure necessitates immediate freshwater rinsing to prevent salt crystal formation and material degradation.

What cleaning products should be avoided when maintaining brushed eva foam sheets

Avoid petroleum-based solvents, strong acids, alkaline cleaners above pH 10, and abrasive compounds that can damage the foam structure or brushed texture. Bleach-based products may cause discoloration, while acetone and similar solvents can dissolve the foam material. Always test cleaning products on inconspicuous areas before full application.

Can pressure washing be used to clean brushed eva foam sheets

Low-pressure water application is acceptable for rinsing, but high-pressure washing can damage the brushed texture and force contaminants deeper into the foam structure. If pressure washing is necessary, use wide fan nozzles, maintain significant distance from the surface, and keep pressure below 500 PSI to prevent surface damage.

How can I restore flattened brush texture after cleaning

Gentle brushing with soft-bristled brushes in the direction of the original texture pattern can help restore flattened fibers. Steam treatment at low temperature may also help restore texture, but requires careful application to prevent thermal damage. Severely flattened areas may require professional restoration or replacement if texture cannot be adequately restored.