High-end boat manufacturers continuously seek innovative materials that deliver exceptional performance, durability, and aesthetic appeal. Among the most significant developments in marine flooring technology is the adoption of EVA foam decking, which has revolutionized how luxury vessels approach deck construction. This advanced material offers a unique combination of functionality and elegance that addresses the demanding requirements of premium marine applications. Modern boat builders recognize that decking materials must withstand harsh marine environments while providing superior comfort and safety for passengers.

Superior Performance Characteristics

Enhanced Safety and Non-Slip Properties

The safety advantages of EVA foam decking make it an invaluable choice for high-end marine vessels. The material's inherent texture provides exceptional grip even when wet, significantly reducing the risk of slips and falls on deck surfaces. This non-slip characteristic becomes particularly crucial during rough sea conditions or when the deck is exposed to spray and moisture. Luxury boat owners and charter operators prioritize passenger safety above all else, making this feature a compelling selling point for premium vessel manufacturers.

The closed-cell structure of EVA foam creates a surface that maintains its grip properties throughout various weather conditions. Unlike traditional decking materials that may become dangerously slippery when wet, EVA foam decking maintains consistent traction levels. This reliability allows passengers to move confidently across the deck, whether they're barefoot or wearing boat shoes, enhancing the overall boating experience and reducing liability concerns for manufacturers and operators.

Exceptional Comfort and Cushioning

Comfort represents another significant advantage that sets EVA foam decking apart from conventional marine flooring options. The material's cushioning properties provide a softer surface underfoot, reducing fatigue during extended periods on deck. This enhanced comfort becomes particularly noticeable during long cruises or when passengers spend considerable time standing or walking on deck surfaces. High-end boat manufacturers recognize that passenger comfort directly impacts the perceived value and luxury appeal of their vessels.

The shock-absorbing qualities of EVA foam also contribute to joint protection and overall passenger well-being. Traditional hard decking materials can cause discomfort and fatigue over time, especially for elderly passengers or those with joint sensitivities. The responsive nature of EVA foam decking provides gentle support that adapts to foot pressure, creating a more pleasant experience for all aboard. This attention to passenger comfort aligns perfectly with the luxury market's expectations for premium marine vessels.

Durability and Weather Resistance

Marine Environment Resilience

The harsh marine environment presents unique challenges that demand exceptional material performance from decking solutions. EVA foam decking demonstrates remarkable resistance to saltwater corrosion, UV degradation, and temperature fluctuations that commonly affect marine vessels. This resilience ensures that the decking maintains its appearance and functionality over extended periods, reducing maintenance requirements and replacement costs for boat manufacturers and owners alike.

Salt exposure, which can rapidly deteriorate many materials, has minimal impact on properly formulated EVA foam decking. The material's chemical composition resists salt crystal formation and corrosion, maintaining structural integrity even after prolonged exposure to seawater. Additionally, the UV-resistant properties prevent the color fading and material degradation that often plague other decking materials exposed to intense sunlight and reflected light from water surfaces.

Longevity and Cost-Effectiveness

High-end boat manufacturers appreciate the long-term value proposition offered by EVA foam decking installations. The material's durability translates into extended service life, reducing the frequency of decking replacement and associated labor costs. This longevity becomes particularly important for luxury vessels where downtime for maintenance can significantly impact charter revenue or owner enjoyment. The initial investment in quality EVA foam decking pays dividends through reduced maintenance expenses and extended replacement intervals.

The material's resistance to cracking, peeling, and delamination ensures consistent performance throughout its service life. Unlike wood or composite decking that may require periodic refinishing or replacement of damaged sections, EVA foam decking maintains its integrity with minimal intervention. This reliability reduces warranty concerns for manufacturers and provides peace of mind for boat owners investing in premium vessels.

Installation and Maintenance Advantages

Simplified Installation Process

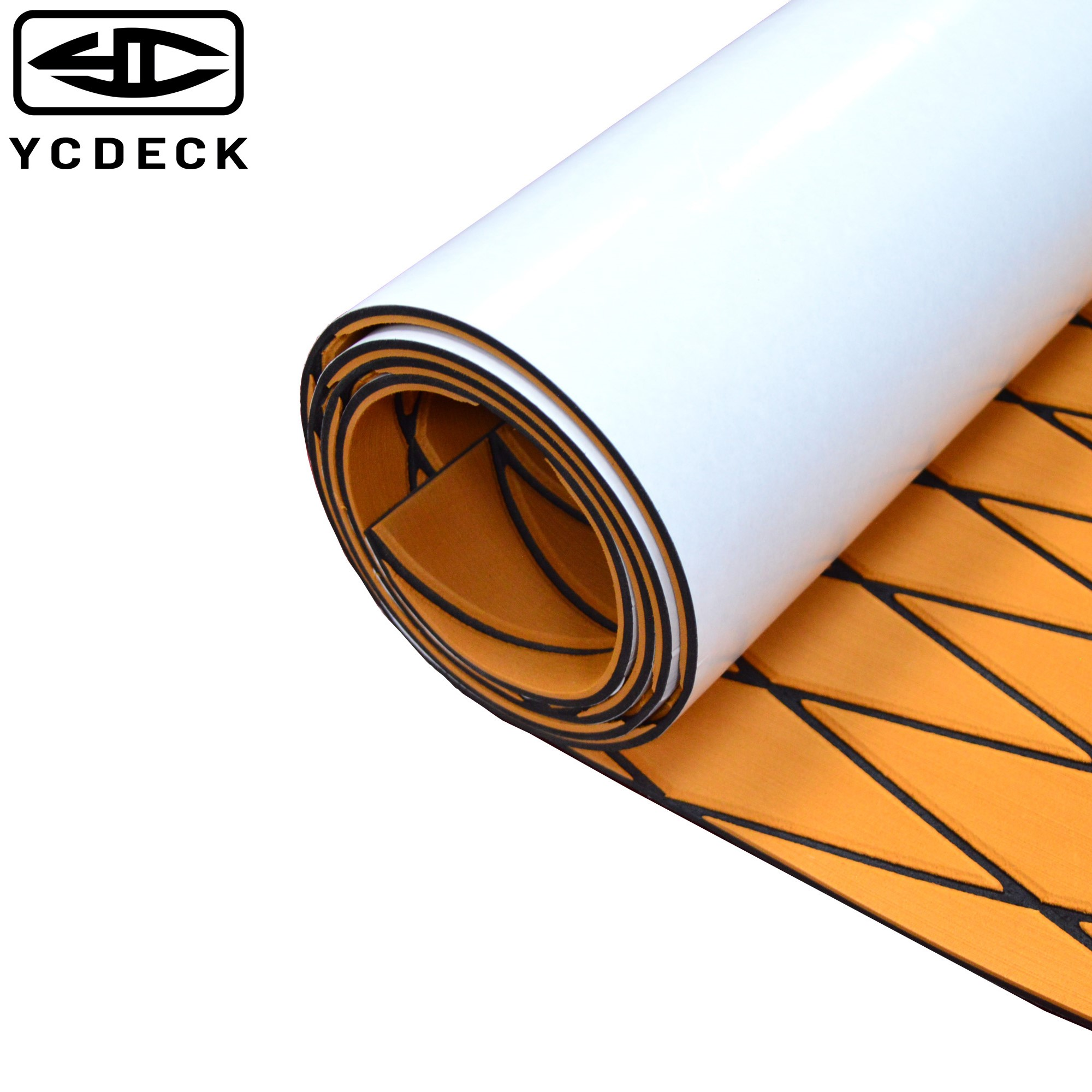

The installation characteristics of EVA foam decking provide significant advantages for boat manufacturers seeking to streamline production processes. The material's flexibility allows for easy conforming to curved surfaces and complex deck geometries common in high-end vessel designs. This adaptability reduces installation time and labor costs while ensuring precise fit and finish that meets luxury market standards. Manufacturers can achieve professional results with standard tools and techniques, eliminating the need for specialized equipment or extensive training.

Many EVA foam decking products feature self-adhesive backing systems that further simplify the installation process. This adhesive technology creates strong, permanent bonds with properly prepared surfaces while eliminating the need for mechanical fasteners that could compromise the deck's waterproof integrity. The adhesive installation method also provides a cleaner appearance without visible fastener heads or seams that might detract from the vessel's premium aesthetic appeal.

Minimal Maintenance Requirements

The maintenance advantages of EVA foam decking align perfectly with the expectations of luxury boat owners who prioritize convenience and minimal upkeep requirements. The material's non-porous surface resists staining and can be easily cleaned with standard marine cleaning products and fresh water. This ease of maintenance reduces the time and effort required to keep decks looking pristine, allowing owners to focus on enjoying their vessels rather than maintaining them.

Regular cleaning typically involves simple washing with mild soap and water, followed by rinsing to remove salt deposits and debris. The material's resistance to mold and mildew growth further reduces maintenance concerns, particularly important in humid marine environments where biological growth can quickly become problematic. This low-maintenance characteristic provides ongoing value for boat owners while reducing warranty service requirements for manufacturers.

Design Flexibility and Aesthetic Appeal

Customization Options

High-end boat manufacturers value the extensive customization possibilities offered by modern EVA foam decking systems. The material can be produced in virtually any color, pattern, or texture to complement specific vessel designs and owner preferences. This flexibility allows manufacturers to create distinctive deck appearances that enhance their brand identity and meet the unique aesthetic requirements of luxury boat buyers. Custom patterns can incorporate logos, decorative elements, or functional features like drainage channels.

Advanced manufacturing techniques enable the creation of wood-grain textures, geometric patterns, and other sophisticated surface treatments that rival traditional materials in visual appeal. These aesthetic options allow boat designers to achieve specific design themes while maintaining the performance advantages of EVA foam construction. The ability to match existing interior colors and materials creates cohesive design schemes that enhance the overall luxury experience aboard premium vessels.

Professional Appearance

The visual quality achievable with EVA foam decking meets the exacting standards expected in the luxury marine market. Clean lines, consistent coloration, and professional installation create deck surfaces that enhance rather than detract from a vessel's overall appearance. The material's ability to maintain its appearance over time ensures that boats continue to look new and well-maintained throughout their service life, protecting resale values and brand reputation.

Edge finishing options and trimming capabilities allow for precise integration with other deck elements, creating seamless transitions and professional installations. The material can be cut and shaped to accommodate hardware, fixtures, and other deck features without compromising structural integrity or water resistance. This versatility enables boat manufacturers to achieve the exact appearance and functionality required for their specific vessel designs.

Environmental and Sustainability Considerations

Eco-Friendly Material Properties

Environmental responsibility increasingly influences purchasing decisions in the luxury marine market, making the sustainability aspects of EVA foam decking particularly relevant. Many EVA foam products incorporate recycled content and can be recycled at the end of their service life, reducing environmental impact compared to traditional decking materials. This sustainability profile appeals to environmentally conscious boat owners who seek to minimize their ecological footprint while enjoying luxury marine experiences.

The manufacturing processes used to produce quality EVA foam decking often generate fewer emissions and waste products compared to traditional wood or composite alternatives. Additionally, the extended service life of EVA foam decking reduces the frequency of replacement, further minimizing environmental impact over the vessel's lifetime. These environmental advantages allow manufacturers to market their vessels to eco-conscious consumers who prioritize sustainability without compromising performance or luxury.

Reduced Chemical Treatments

Unlike wood decking that requires regular treatment with potentially harmful chemicals for preservation and maintenance, EVA foam decking eliminates the need for such interventions. This reduction in chemical usage benefits both the marine environment and vessel occupants by minimizing exposure to potentially toxic substances. The inherent properties of EVA foam provide necessary protection against marine hazards without requiring additional chemical treatments that could leach into surrounding waters.

The elimination of chemical treatments also simplifies maintenance procedures and reduces ongoing costs for boat owners. There's no need to purchase, store, or apply protective coatings, stains, or sealers that are commonly required for other decking materials. This simplification benefits both manufacturers and owners while supporting environmental protection efforts in sensitive marine ecosystems where chemical runoff can cause significant ecological damage.

FAQ

How long does EVA foam decking typically last on marine vessels

Quality EVA foam decking systems can provide 10-15 years of reliable service when properly installed and maintained. The actual lifespan depends on factors such as UV exposure, usage intensity, and maintenance practices. High-end formulations with advanced UV protection and marine-grade construction often exceed these timeframes, making them excellent long-term investments for luxury vessel applications.

Can EVA foam decking be repaired if damaged

Yes, EVA foam decking can often be repaired using patch kits and specialized adhesives designed for marine applications. Small punctures, cuts, or wear areas can typically be addressed without replacing entire sections. However, the repair quality depends on the damage extent and the skill of the person performing the work. Professional installation and repair services ensure the best results and maintain warranty coverage.

What thickness options are available for EVA foam decking

EVA foam decking is commonly available in thicknesses ranging from 6mm to 10mm, with some specialty applications requiring custom thicknesses. Thicker materials provide enhanced comfort and cushioning but may affect door clearances and transitions to other surfaces. The optimal thickness depends on the specific application, expected usage, and integration requirements with existing vessel systems and fixtures.

Is EVA foam decking suitable for all areas of a boat

While EVA foam decking excels in most marine applications, certain high-wear areas or specialized environments may require alternative solutions. Areas subject to extreme heat, sharp objects, or heavy equipment may benefit from harder surface materials. However, the majority of deck areas, including walkways, seating areas, and recreational spaces, are ideal candidates for EVA foam decking installation, providing excellent performance and passenger comfort.