fabricant de coussins de gouvernail en Chine

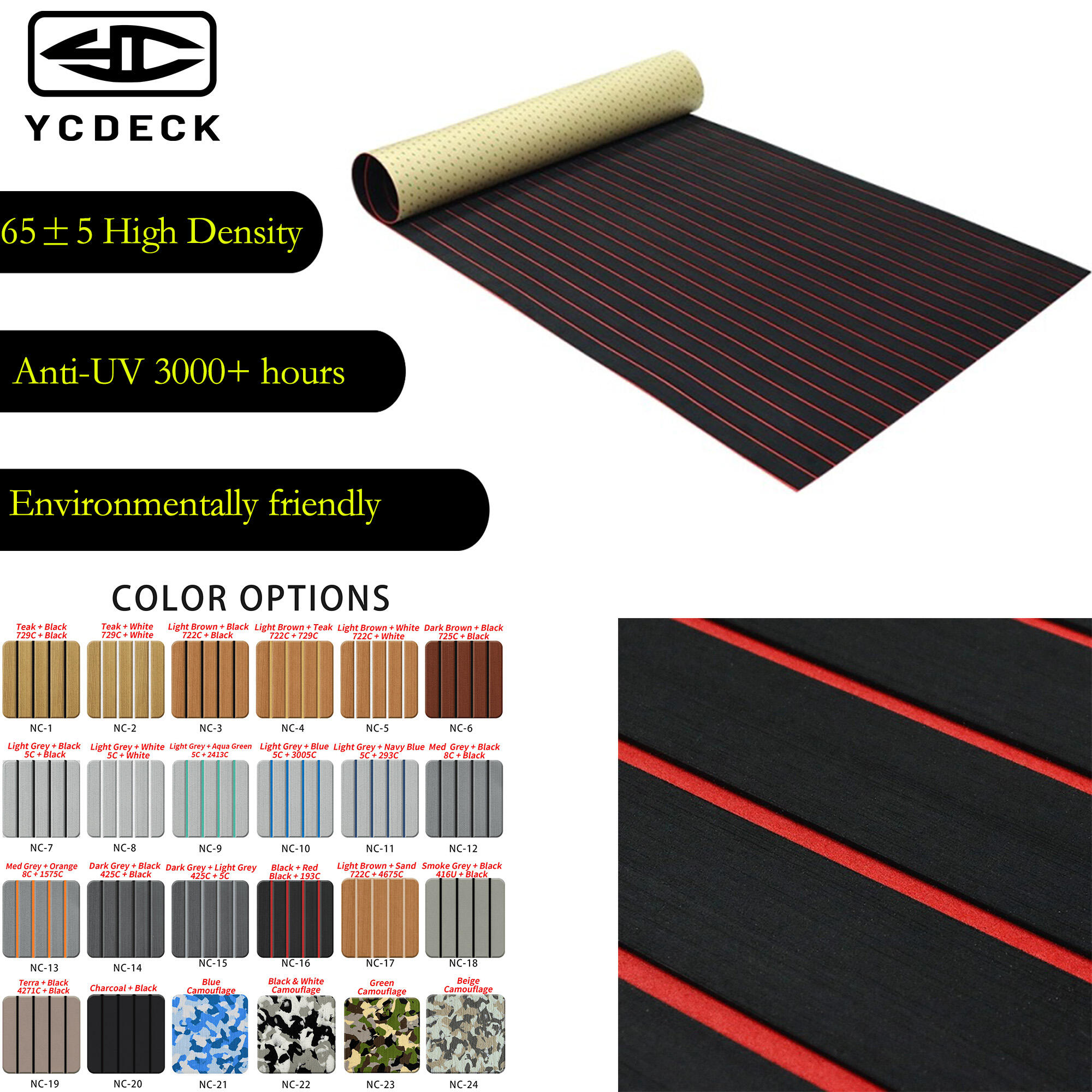

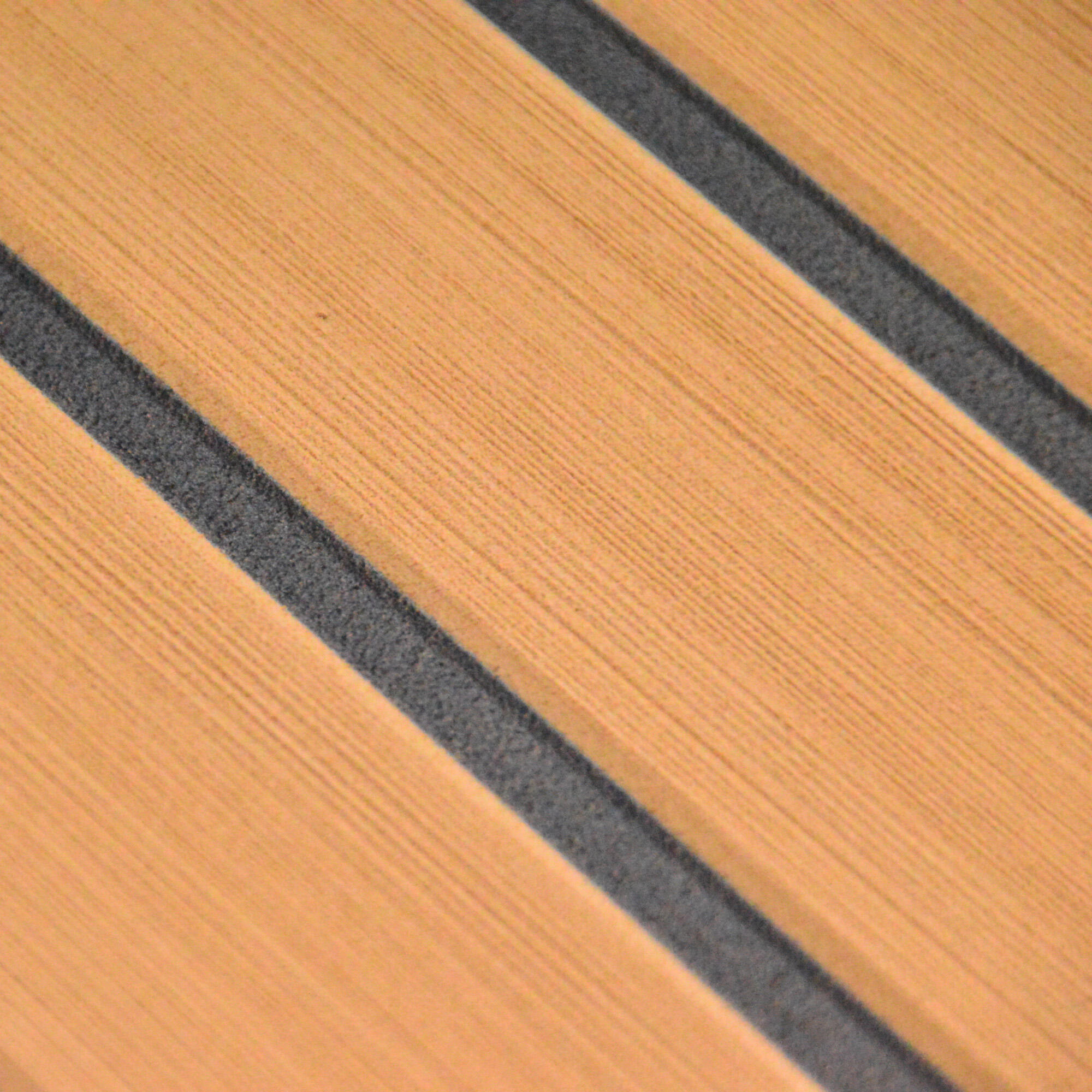

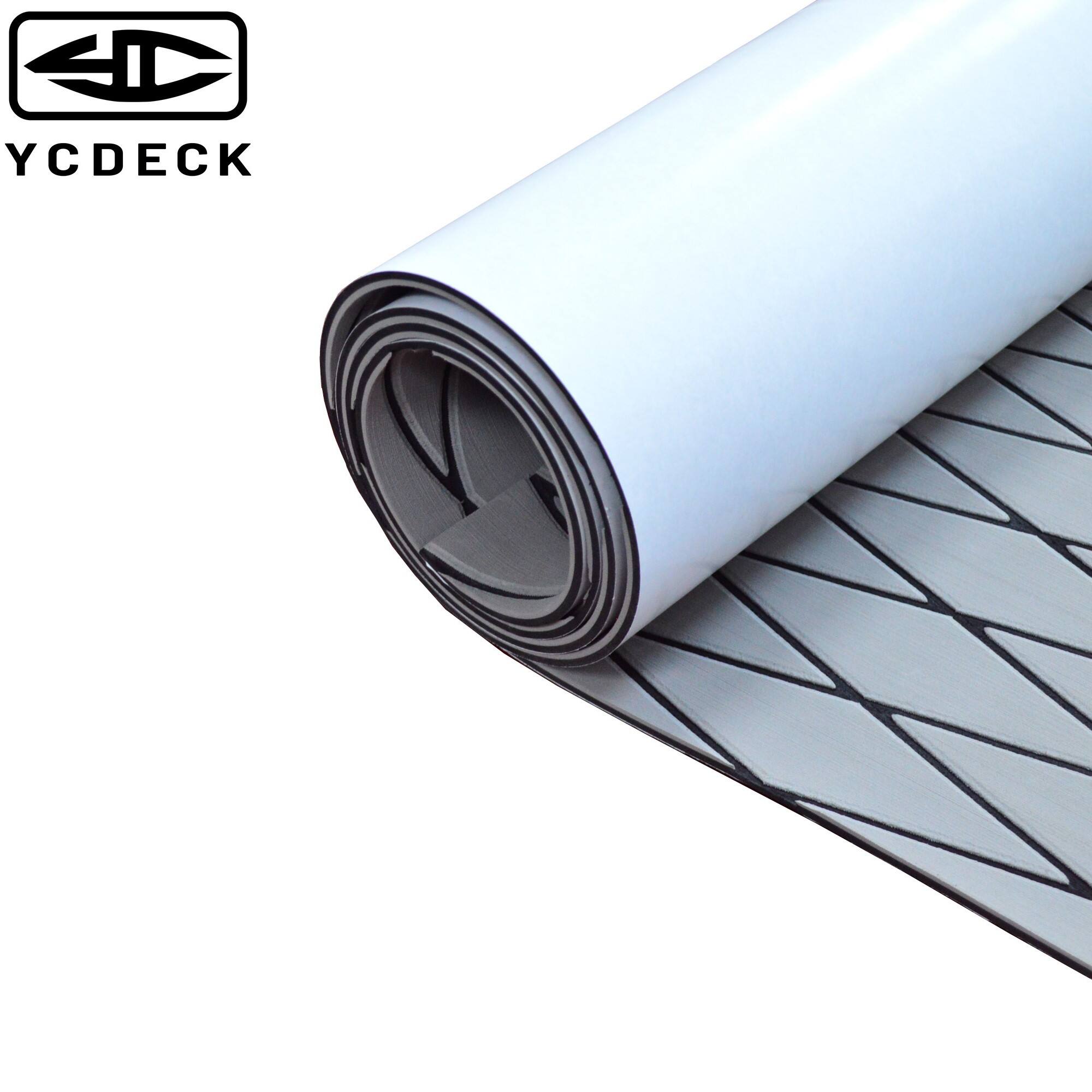

Un fabricant de pads de barre chinois se trouve à la pointe de la production d'équipements maritimes, spécialisée dans la création de pads de barre de haute qualité qui assurent un contrôle et un confort optimaux pour les opérateurs de navires. Ces fabricants utilisent des processus de fabrication avancés et des matériaux premium pour produire des pads de barre conformes aux normes maritimes internationales. Les installations comprennent généralement des lignes de production modernes équipées d'outils de découpe précis et de systèmes de contrôle qualité. Leurs pads de barre sont conçus pour résister aux environnements maritimes rigoureux, offrant une résistance supérieure à la radiation UV, à l'exposition à l'eau salée et aux conditions météorologiques extrêmes. Le processus de fabrication intègre des conceptions ergonomiques innovantes qui réduisent la fatigue de l'opérateur pendant des périodes prolongées à la barre. Ces installations maintiennent des mesures strictes de contrôle qualité tout au long du cycle de production, de la sélection des matières premières aux tests finaux du produit. Les pads de barre sont disponibles en différentes tailles et configurations pour répondre aux besoins de différents types de navires, des petits bateaux de loisir aux grands navires commerciaux. Des technologies polymères avancées sont utilisées pour garantir une durabilité à long terme tout en maintenant un confort tactile. Les fabricants proposent également des options de personnalisation, y compris des conceptions marquées et des exigences dimensionnelles spécifiques pour répondre aux besoins individuels des clients.