sztuczny materiał na pokład łodzi

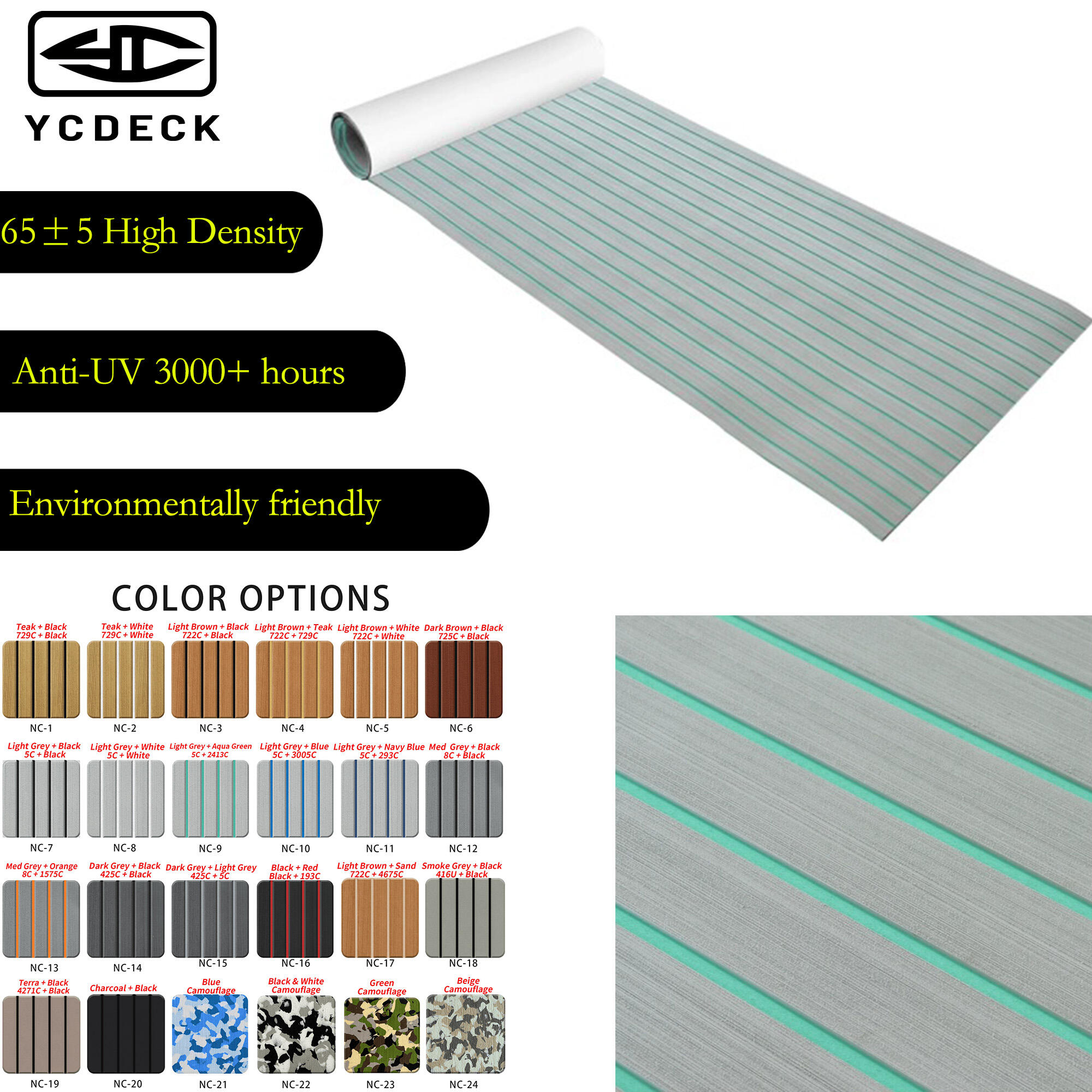

Materiał syntetyczny na pokład statku reprezentuje rewolucyjne osiągnięcie w technologii podłóg morskich, oferując nowoczesną alternatywę dla tradycyjnego dębowego pokrycia. Ten innowacyjny materiał łączy związków polimerowych o wysokiej gęstości z zaawansowanymi procesami produkcyjnymi, tworząc przy tym trwałą, odporną na warunki atmosferyczne powierzchnię, która zachowuje klasyczny wygląd drewna naturalnego. Materiał jest zaprojektowany tak, aby wytrzymać surowe środowiska morskie, w tym stały kontakt z wodą morską, promieniowaniem UV i ekstremalnymi zmianami temperatury. Jego tekstura antypoślizgowa zapewnia bezpieczeństwo w warunkach mokrych, podczas gdy specjalny skład uniemożliwia absorpcję wody oraz opór przed plamami, pleśnią i grzybem. Syntetyczne pokrycie posiada zintegrowane stabilizatory UV, które zapobiegają blakaniu i utrzymują spójność koloru przez całą jego żywotność. Montaż obejmuje precyzyjnie zaprojektowany system zaczepów, który tworzy szczelny połączenie między panelami, eliminując obawy związane z przenikaniem wody. Struktura komórkowa materiału zapewnia doskonałe tłumienie wstrząsów i komfort pod stopami, co czyni go idealnym do długotrwałego użytkowania pokładu. Nowoczesne techniki produkcyjne pozwalają na niestandardowe opcje kolorów i wzorów, umożliwiając właścicielom statków uzyskanie pożądanego estetycznego efektu, jednocześnie zachowując praktyczne funkcje.