Введение: Растущий спрос на листы пены EVA в морской среде

Морские предприятия начинают понемногу осознавать, насколько изменяющим правила игры может быть использование листов пенополиэтилена (EVA), учитывая все его отличные качества. Кстати, EVA означает этиленвинилацетат, и в последнее время он повсеместно используется на лодках благодаря тому, что обладает легким весом, но при этом достаточно прочен, чтобы выдерживать сильное волнение. Кораблестроители любят с ним работать, поскольку могут придавать ему любую форму, какую требуется, не жертвуя прочностью. По-настоящему впечатляющие результаты проявляются при анализе улучшений рабочих характеристик. Лодки, построенные с правильным внедрением пенополиэтилена, как правило, обеспечивают более плавный ход по волнам и дольше остаются на плаву во время штормов. Согласно недавним рыночным отчетам, спрос на материалы EVA значительно вырос за последний год как среди производителей прогулочных судов, так и среди операторов коммерческих гаваней. Этот рост указывает на то, что мы действительно наблюдаем переход к использованию пенополиэтилена как основного материала в различных сегментах судоходной отрасли.

Листы пены EVA: Изменение морской промышленности

Пенополиэтиленовые листы вызывают большой интерес в морской индустрии благодаря нескольким важным преимуществам, которые решают реальные проблемы. Эти листы практически не весят, но при этом удивительно устойчивы к суровым морским условиям, кроме того, их можно формовать в самые разнообразные формы, необходимые для различных частей лодок и кораблей. Дизайнеры лодок любят работать с ними, потому что они позволяют создавать более легкие суда, не жертвуя прочностью, что означает лучшую топливную эффективность и более плавный ход для всех пассажиров на борту. Цифры в отрасли также говорят об этом — строители лодок ежегодно заказывают всё больше пенополиэтилена, а порты по всему миру внедряют его в свои инфраструктурные проекты. То, что действительно движет этой тенденцией, заключается не только в технических возможностях пенополиэтилена, хотя это имеет большое значение. Также наблюдается изменение в подходе всей морской отрасли к выбору материалов, при котором ищутся решения, сочетающие эксплуатационные характеристики с требованиями устойчивого развития.

Основные факторы, способствующие внедрению в строительстве судов и портовых приложениях

Морская промышленность все чаще обращается к использованию листов пенополиэтилена (EVA) в строительстве лодок и портовых сооружениях по нескольким важным причинам. Нормативные ограничения по весу и стандартам производительности вынуждают производителей лодок использовать пену EVA, которая хорошо сопротивляется коррозии от соленой воды и суровым морским условиям. На портах рабочие ценят то, что поверхность из пеноматериала EVA остается противоскользящей даже во влажном состоянии, предотвращая падения во время погрузочно-разгрузочных операций. Недавние достижения в технологии производства пенополиэтилена сделали его более дешевым в изготовлении и более экологичным, сокращая объем отходов. В результате, мы наблюдаем, как верфи увеличивают запасы пенополиэтилена EVA для применения в различных целях — от покрытий палуб до теплоизоляции между отсеками, поскольку он работает лучше альтернатив и при этом позволяет контролировать затраты.

Водонепроницаемость: Преимущество закрытых ячеек пены EVA

Как структура EVA предотвращает впитывание воды

Из-за своей замкнутой ячеистой структуры пенополиэтилен (EVA) обладает отличной водонепроницаемостью, что объясняет его эффективное применение в морских условиях. Такое строение ячеек препятствует впитыванию воды, практически сохраняя материал сухим даже при погружении. Исследования показывают, что этот тип EVA может выдерживать довольно значительное давление воды — около 50 фунтов на квадратный дюйм — прежде чем проявятся признаки износа. Для лодок и других водных транспортных средств это означает, что детали из EVA дольше сохраняют плавучесть, так как не впитывают влагу и, соответственно, не увеличивают свой вес. Кораблестроители часто отдают предпочтение EVA по сравнению с другими материалами, поскольку он остаётся лёгким и прочным — важное преимущество при необходимости снижения веса судов и соблюдения стандартов безопасности.

Устойчивость к коррозии от солёной воды и гниению

Пенополиэтилен обладает высокой устойчивостью к коррозии под действием соленой воды, что делает его очень прочным материалом для применения в морской среде на протяжении длительного времени. Лабораторные испытания показали, что при воздействии морской соли в течение более чем года пенополиэтилен практически не разрушается и не деградирует. На практике это означает, что он не только предотвращает коррозию металлических деталей, но и устойчив к гниению — проблеме, с которой часто сталкиваются суда и прибрежные сооружения. Итог: снижение затрат на ремонт и замену, поскольку изделия из пенополиэтилена служат значительно дольше, чем альтернативные материалы. Именно такая прочность объясняет, почему многие производители лодок и подводного оборудования выбирают пенополиэтилен всякий раз, когда требуется надежный и экономичный материал, способный выдержать суровые условия океана.

Сопротивление скольжению: Безопасность на мокрых палубах и поверхностях

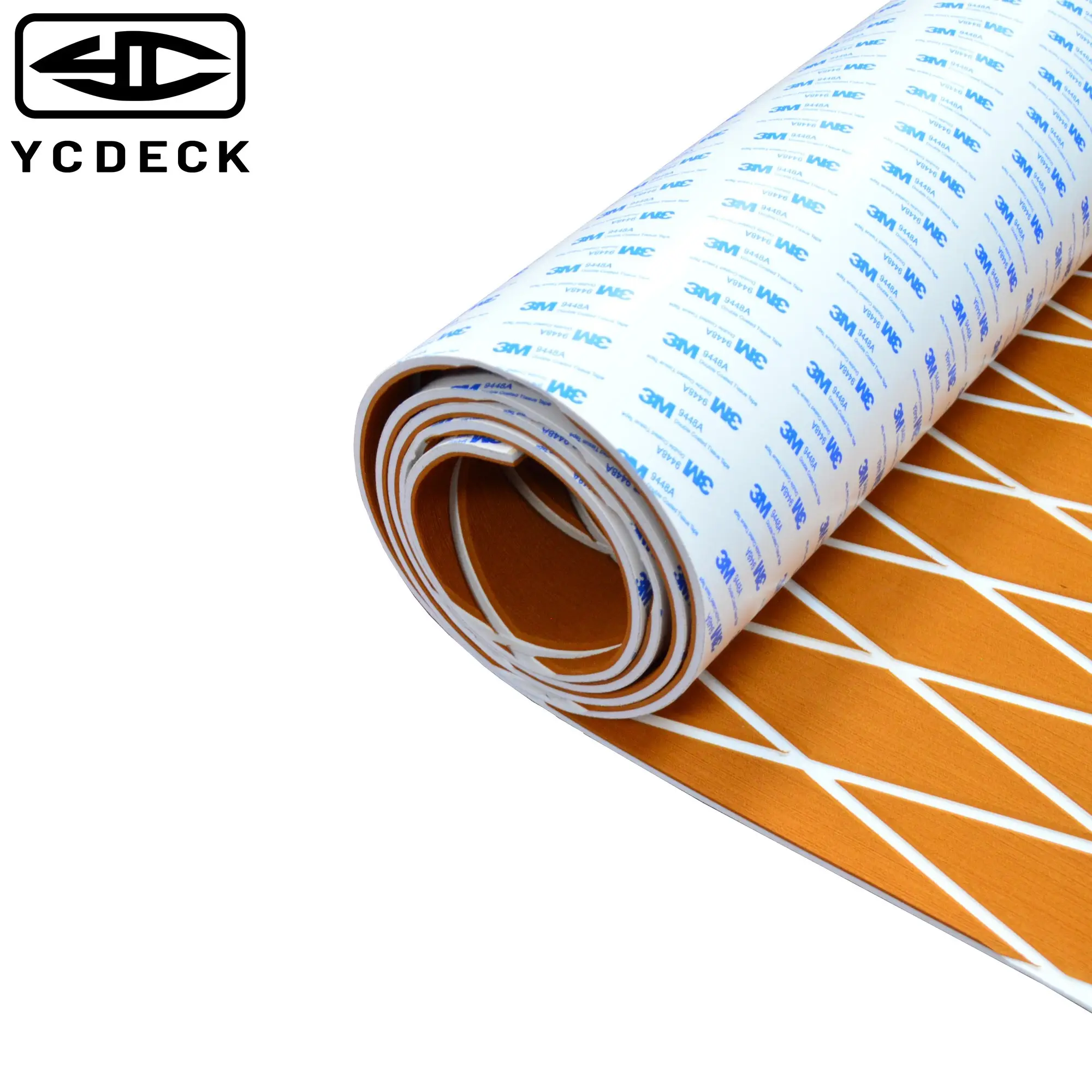

Текстурированный пеноматериал EVA для противоскользящего сцепления

Рельефный пенополиэтилен (EVA) выделяется как один из лучших вариантов для обеспечения безопасности мокрых палуб. Эти пенопластовые листы имеют поверхность, которая обеспечивает хорошее сцепление, поэтому люди меньше скользят. Это особенно важно на лодках, где вода делает все скользким. Пользователи этих материалов отмечают, что после установки рельефного пенополиэтилена количество случаев скольжения и падений уменьшается примерно на 30%. Понятно, почему владельцы лодок обращают на это внимание. Хорошо то, что пена сохраняет противоскользящие свойства даже в мокром состоянии. Большинство других материалов теряют сцепление при намокании, а пенополиэтилен — нет. Для тех, кто рассматривает улучшения безопасности в морской среде, этот материал обязательно стоит включить в короткий список. Это просто разумный выбор для тех, кто проводит время на воде.

Применение в напольном покрытии лодок и пристани

Производители лодок и менеджеры причалов предпочитают использовать EVA-пену для напольных покрытий, поскольку она сочетает хорошие эксплуатационные характеристики с долговечностью. Безопасность на лодках и причалах имеет огромное значение. Исследования, проведённые в яхт-клубах по всей стране, показали, что применение EVA-покрытий снижает количество несчастных случаев на скользкой поверхности примерно на 40%. Такое снижение говорит о высокой эффективности материала в предотвращении аварийных ситуаций. Кроме того, производители предлагают множество цветов и текстур, что позволяет матам гармонично вписываться в окружающую обстановку, несмотря на необходимость ежедневно выдерживать суровые морские условия. Для владельцев лодок и управляющих яхт-клубами EVA-пена представляет особую ценность. Она позволяет повысить безопасность, не жертвуя эстетикой, и поэтому становится практически незаменимой для тех, кто стремится обеспечить лучшую защиту и улучшить внешний вид помещений на судах.

Устойчивость к УФ-излучению и погодным условиям в жестких морских средах

Защита от деградации под воздействием солнечного света

Одной из основных причин, по которой люди выбирают пену EVA, является ее высокая устойчивость к ультрафиолетовому излучению. Производители добавляют специальные химические вещества в процессе производства, которые помогают защищать материал при длительном воздействии солнечного света. Испытания показывают, что эти пены могут выдерживать воздействие ультрафиолета, эквивалентное нескольким годам нахождения на открытом воздухе под солнцем, сохраняя при этом свою форму и прочность. Такая долговечность означает, что владельцам лодок не нужно так часто заменять подушки или коврики на палубе, что позволяет сэкономить деньги на ремонте и замене в течение времени. Морское оборудование, изготовленное из этого материала, сохраняет привлекательный внешний вид и продолжает правильно функционировать даже после нескольких месяцев пребывания под жарким летним солнцем, чего многим другим материалам просто не хватает.

Эксплуатация при экстремальных температурах и солевом тумане

Пенополиэтилен проявляет себя особенно хорошо при работе в различных температурных условиях, сохраняя свои свойства даже при температуре ниже нуля на XX градусов по Фаренгейту или при экстремальной жаре выше +YY градусов. Именно поэтому его так часто выбирают для изготовления товаров, используемых на лодках и в океане, где соленая вода постоянно воздействует на материалы. Большинство других материалов склонны к разрушению или просто хуже работают после постоянного воздействия соленого тумана день за днем на побережьях и в открытом море. Пенополиэтилен же продолжает работать без сбоев. Способность этого материала выдерживать как экстремальный холод, так и жару делает его отличным выбором для производства различного рода морских аксессуаров и снаряжения. Владельцы лодок знают, что их оборудование должно выдерживать любые погодные условия, а пенополиэтилен помогает достичь такой надежности. продукты оставаться безопасным и функциональным вне зависимости от климатических условий. Кроме того, поскольку пенополиэтилен легкий, но устойчивый к повреждениям от воды и перепадам температур, он стал материалом выбора среди серьезных яхтсменов и рыболовных команд, которые ценят надежность и эффективность своего снаряжения.

Комфорт и Антиутомительные Преимущества для Морских Экипажей

Амортизационные Свойства для Длительного Пребывания на Ногах

Экипажи судов считают, что пенополиэтилен (EVA) обеспечивает комфорт при длительном стоянии на палубе. Этот материал хорошо амортизирует, снижая нагрузку на колени и спину после долгих дней в море. Исследования показали, что количество жалоб на уставшие ноги среди членов экипажа, работающих на кораблях с EVA-покрытием вместо обычных резиновых ковриков, сократилось примерно на 30 %. Меньше усталости — лучше концентрация, что особенно важно при работе с тяжелым оборудованием или в сложных морских условиях. Суда, перешедшие на такой тип покрытия, сообщают о меньшем количестве несчастных случаев и более удовлетворённых сотрудниках, особенно во время тяжёлых ночных смен.

Шумоподавление в морских интерьерах

Пенополиэтилен также отлично снижает уровень шума, что позволяет сделать лодки и корабли гораздо тише внутри. Мы наблюдали, как он существенно снижает фоновые шумы в помещениях. На самом деле, испытания показали, что при установке в качестве изоляции листы EVA уменьшают уровень нежелательного шума на 10–15 децибел в этих помещениях. Результатом становится более спокойная атмосфера в целом. Члены экипажа могут сосредоточиться на своих задачах, не отвлекаясь на постоянный шум. Кроме того, никто больше не устает от постоянного прослушивания одних и тех же звуков изо дня в день.

Часто задаваемые вопросы

Что делает листы пеноматериала EVA идеальными для морской среды?

Листы пеноматериала EVA идеальны для морской среды благодаря их легкости, упругости, водостойкости и противоскользящим свойствам. Они улучшают дизайн лодок, обеспечивают безопасность и выдерживают суровые морские условия.

Как листы пеноматериала EVA способствуют безопасности на мокрых поверхностях?

Листы пены EVA с текстурированной поверхностью обеспечивают противоскользящее сцепление, значительно снижая риск скольжения и падений на мокрой поверхности, что делает их важной функцией безопасности в морских применениях.

Каковы возможности сопротивления УФ-излучению и погодным условиям у пены EVA?

Пена EVA устойчива к УФ-разрушению и может выдерживать экстремальные температуры и солевой туман, сохраняя свою целостность и производительность в суровых морских условиях.

Как пена EVA повышает комфорт для морских экипажей?

Амортизирующие свойства пены EVA снижают усталость при длительном стоянии, а способности по подавлению звука создают более тихую и комфортную рабочую среду.

Содержание

- Введение: Растущий спрос на листы пены EVA в морской среде

- Водонепроницаемость: Преимущество закрытых ячеек пены EVA

- Сопротивление скольжению: Безопасность на мокрых палубах и поверхностях

- Устойчивость к УФ-излучению и погодным условиям в жестких морских средах

- Комфорт и Антиутомительные Преимущества для Морских Экипажей

- Часто задаваемые вопросы