Introduction: Rising Demand for EVA Foam Sheets in Marine Environments

Marine businesses are starting to see just how game changing EVA foam sheets can be because of all their great qualities. EVA stands for Ethylene-Vinyl Acetate by the way, and it's showing up everywhere on boats these days thanks to being light weight yet tough enough to handle rough seas. Boat builders love working with it since they can shape it however needed without compromising strength. The real magic happens when looking at actual performance improvements too. Boats built with proper EVA foam integration tend to ride smoother through waves and stay buoyant longer during storms. According to recent market reports, demand for EVA materials has jumped quite a bit over the past year among both recreational vessel makers and commercial harbor operators. This surge suggests we're seeing a real shift towards EVA as the go to material solution across different parts of the shipping world.

EVA Foam Sheets: A Marine Industry Game-Changer

EVA foam sheets are making waves across the marine industry thanks to several key benefits that address real world problems. These sheets weigh next to nothing yet stand up surprisingly well against harsh conditions at sea, plus they can be shaped into all sorts of forms needed for different parts of boats and ships. Boat designers love working with them because they allow for lighter vessels without sacrificing durability, which means better fuel efficiency and smoother rides for everyone onboard. Industry numbers tell the story too – boat builders have been ordering more EVA foam each year while ports around the world are incorporating it into their infrastructure projects. What's really driving this trend isn't just about what EVA foam can do technically, though that matters a lot. There's also something happening in how the whole marine business thinks about materials these days, looking for solutions that balance performance with sustainability concerns.

Key Factors Driving Adoption in Boatbuilding and Port Applications

The marine industry is increasingly turning to EVA foam sheets for boat construction and port facilities because of several important reasons. Regulations around weight restrictions and performance standards have pushed boat manufacturers toward EVA foam, which holds up well against saltwater corrosion and rough seas. At ports, workers appreciate how EVA foam stays grippy even when wet, preventing slips during cargo loading and unloading operations. Recent advances in how EVA foam is produced have made it both cheaper to manufacture and better for the environment, cutting down on waste materials. As a result, we're seeing more shipyards stockpile EVA foam for everything from deck surfaces to insulation between compartments, since it simply works better than alternatives while keeping costs under control.

Water Resistance: The Closed-Cell Advantage of EVA Foam

How EVA's Structure Prevents Water Absorption

The closed cell structure of EVA foam is what gives it those great water resistant properties, which explains why it works so well in marine environments. The way these cells are arranged stops water from getting absorbed into the material, basically keeping it dry even when submerged. Research shows that this type of EVA can handle pretty decent water pressure around 50 pounds per square inch before showing any signs of wear. For boats and other watercraft, this means parts made from EVA stay buoyant longer since they don't soak up extra weight from moisture. Boat builders often prefer EVA over alternatives because it stays lightweight yet strong, something that matters a lot when trying to keep vessel weights down while still meeting safety standards.

Resistance to Saltwater Corrosion and Rot

EVA foam stands up really well against saltwater corrosion, which makes it pretty tough stuff for things that need to last in marine environments over time. Tests done in labs have shown that when exposed to sea salt for more than a year straight, EVA foam doesn't break down or degrade much at all. What this means practically is that besides stopping metal parts from rusting, it actually fights off rot too something that plagues lots of boats and coastal structures. The bottom line? Less money spent on repairs and replacements because whatever gets made with EVA lasts way longer than alternatives. That kind of toughness explains why so many boat builders and underwater equipment manufacturers turn to EVA foam whenever they want something that will hold up through harsh ocean conditions without breaking the bank.

Slip Resistance: Safety on Wet Decks and Surfaces

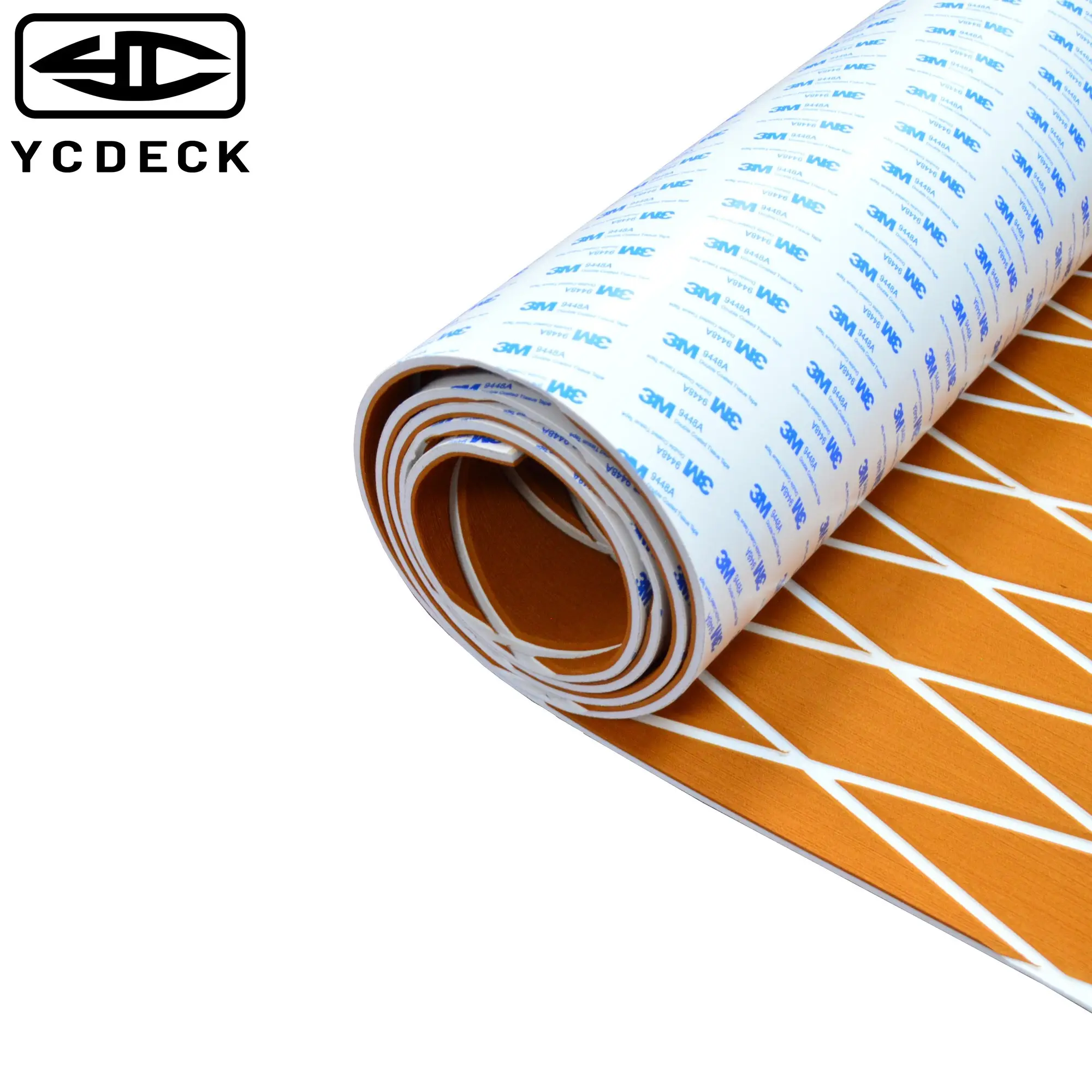

Textured EVA Foam for Non-Slip Traction

Textured EVA foam stands out as one of the best options for keeping wet decks safe. These foam sheets have a surface that really grabs hold, so people don't slip around as much. That matters a lot on boats where water makes everything slippery. People who actually use these materials report about 30% fewer slips and falls after adding textured EVA foam to their vessels. Makes sense why boat owners care about this stuff. What works well is how the foam stays grippy even when soaked. Most other materials lose traction when wet, but not EVA foam. For anyone looking at safety improvements for marine environments, this material should definitely be on the short list. It just makes good practical sense for anyone spending time on the water.

Applications in Boat Flooring and Dock Mats

Boat builders and dock managers love using EVA foam for their flooring needs because it combines good safety features with lasting durability. Safety really matters on boats and docks after all. Studies from marinas around the country indicate that EVA mats cut down slip accidents by roughly 40%. That kind of drop in accidents speaks volumes about how well this material works at preventing mishaps. Plus, manufacturers offer lots of different colors and textures so the mats don't look out of place aesthetically even though they need to handle rough marine conditions daily. For anyone who owns a boat or runs a marina, EVA foam provides something special. It lets them upgrade safety without sacrificing looks, making it pretty much indispensable for those wanting better protection and nicer appearance in their watercraft spaces.

UV and Weather Durability in Harsh Marine Conditions

Protection Against Sunlight Degradation

One of the main reasons people choose EVA foam is because it stands up really well against UV damage. Manufacturers add special chemicals during production that help protect the material when exposed to sunlight for long periods. Tests show these foams can handle UV exposure equivalent to what they'd get from years of sitting outside in the sun, all while keeping their shape and strength intact. This kind of lasting power means boat owners don't have to replace their cushions or deck mats as often, which saves money on repairs and replacements over time. Marine equipment made with this stuff stays looking good and works properly even after months of baking in the hot summer sun, something many other materials just can't handle.

Performance in Extreme Temperatures and Salt Spray

EVA foam really shines in how well it handles different temperatures, staying intact even when temps drop below freezing at -XX degrees Fahrenheit or soar past +YY degrees. That's why so many people turn to it for stuff used on boats and in the ocean where saltwater constantly attacks materials. Most other stuff tends to break down or just doesn't work as well after getting hit by salt spray day after day along coastlines and out at sea. But EVA keeps performing without issues. The fact that this material can handle both extreme cold and heat makes it great for making all sorts of marine gear and accessories. Boat owners know their equipment needs to last through whatever weather comes along, and EVA helps ensure those products stay safe and functional no matter what climate they face. Plus, since EVA is light weight yet tough against water damage and temperature swings, it has become the go to material among serious boaters and fishing crews who need reliable performance from their gear.

Comfort and Anti-Fatigue Benefits for Marine Crews

Cushioning Properties for Extended Standing

Marine crews find EVA foam really comfortable when they need to stand around for hours on deck. The stuff cushions pretty well, taking some of the strain off their knees and backs after long days at sea. Studies have shown somewhere around 30% fewer complaints about tired legs among crew members who work on ships fitted with EVA flooring instead of regular rubber mats. Less fatigue means better concentration too, which makes all the difference when handling heavy equipment or navigating rough waters. Ships that switched to this kind of flooring report fewer accidents and generally happier staff, especially during those grueling overnight shifts.

Sound Dampening in Marine Interiors

EVA foam works really well at cutting down on noise too, which means boats and ships can be much quieter inside. We've seen it make quite a difference in lowering background sounds around the place. Tests actually show that when EVA sheets get installed as insulation, they cut out somewhere between 10 to 15 decibels worth of unwanted noise in those spaces. The result? A calmer atmosphere overall. Crew members find themselves able to focus on their tasks without getting distracted by all that constant racket. Plus, nobody gets so tired from listening to the same old sounds day after day anymore.

FAQ

What makes EVA foam sheets ideal for marine environments?

EVA foam sheets are ideal for marine environments due to their lightweight, resilience, water resistance, and non-slip properties. They enhance boat designs, provide safety, and withstand harsh marine conditions.

How do EVA foam sheets contribute to safety on wet surfaces?

EVA foam sheets with textured surfaces provide non-slip traction, significantly reducing slips and falls on wet surfaces, making them an essential safety feature in marine applications.

What are the UV and weather resistance capabilities of EVA foam?

EVA foam is resistant to UV degradation and can withstand extreme temperatures and salt spray, maintaining its integrity and performance in harsh marine conditions.

How does EVA foam enhance comfort for marine crews?

EVA foam's cushioning properties reduce fatigue during prolonged standing, while sound dampening capabilities create a quieter and more comfortable working environment.