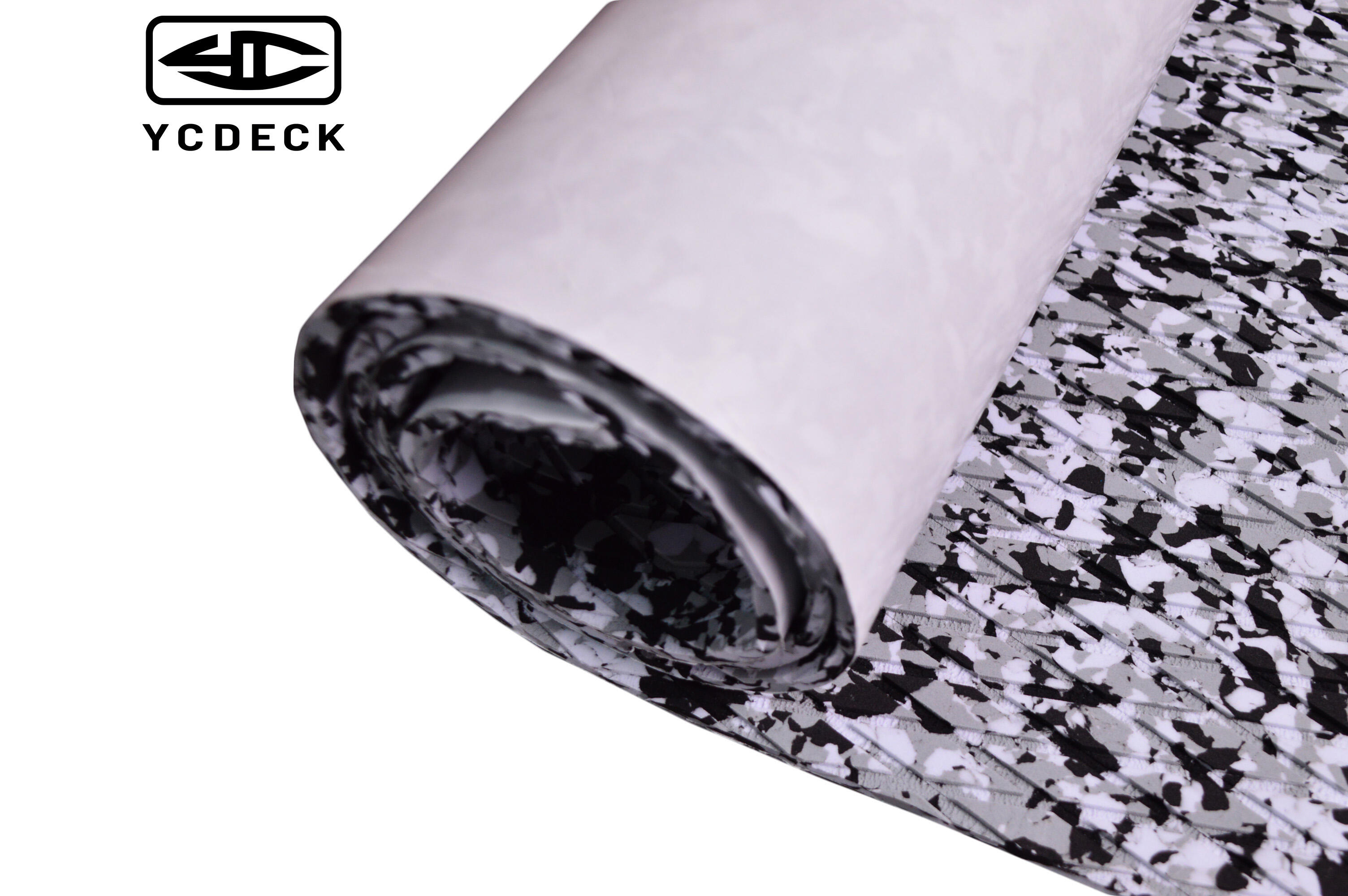

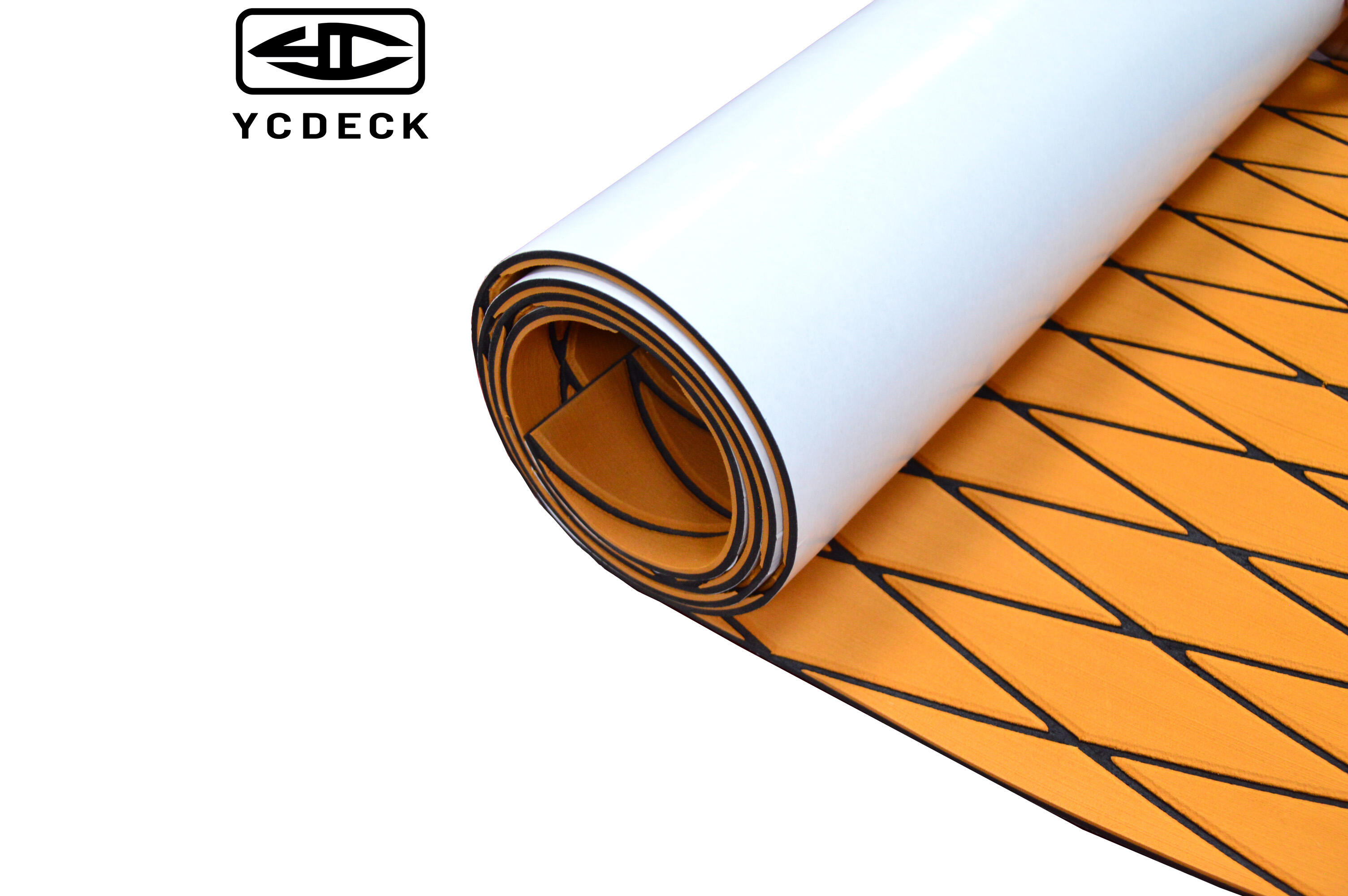

eva foam sheets factory direct

EVA foam sheets factory direct represents a revolutionary approach in material manufacturing, offering customers direct access to high-quality EVA foam products without intermediary markups. These versatile sheets are manufactured using advanced production techniques that ensure consistent density, precise thickness control, and superior material integrity. The manufacturing facility employs state-of-the-art equipment to produce EVA foam sheets in various densities, sizes, and colors, catering to diverse industrial and commercial applications. The direct factory model enables real-time quality control, customization options, and rapid production adjustments based on client specifications. Each sheet undergoes rigorous testing for durability, flexibility, and resistance to environmental factors, ensuring optimal performance across different uses. The factory's integrated production line incorporates automated cutting systems, density control mechanisms, and advanced curing processes to maintain product consistency. Whether for packaging solutions, sports equipment, educational materials, or construction applications, these factory-direct sheets offer superior shock absorption, water resistance, and thermal insulation properties.