Superior Durability in Harsh Marine Conditions

Advanced UV Protection Systems

Boat deck flooring just won't last long without proper UV protection, especially out on the water where those harsh sun rays take their toll. We've all seen what happens when boats sit in the sun too long - materials break down, colors fade away, and eventually the whole deck starts to fall apart. That's why today's marine flooring comes with special additives that soak up UV radiation plus coatings specifically made to fight off sun damage. These protective layers help keep decks looking good for years while also making sure they stay strong enough to handle daily use. Boat owners who invest in quality UV protection typically notice their decks hold up much better than ones left unprotected, saving money on replacements down the road.

Saltwater-Resistant Material Science

Boat decks face serious problems from saltwater exposure, which affects how we choose materials for the floor surfaces. When boats sit in seawater for extended periods, the metal starts corroding, plastics break down, and wood gets weakened over time. Material scientists have recently developed new compounds that fight back against salt damage, making marine flooring last much longer. These innovations allow manufacturers to create floors that actually stand up to the harsh effects of ocean salt without falling apart. Real world tests show these special materials hold together far better than old fashioned options did. Boat builders around the world are now switching to these salt resistant materials because they simply work better in actual sailing conditions.

Anti-Corrosion Structural Integrity

Keeping marine flooring free from corrosion is essential if it's going to last any length of time out there on the water. When left unprotected, common flooring materials just break down faster when exposed to saltwater and constant moisture. Boat builders typically apply several different approaches to stop this damage before it starts. Special paint jobs, zinc coatings applied during manufacturing, and even using certain metals that naturally resist rust all work together to keep decks intact. Industry tests back this up too many times over, showing that properly treated surfaces stay strong much longer than their untreated counterparts. For anyone who spends good money on quality boat decking, these protective treatments mean fewer repairs down the road and safer conditions for crew members walking around wet surfaces without worrying about slipping through compromised wood.

Optimized Slip Resistance for Boat Safety

Micro-Texture Surface Designs

The micro texture patterns on boat deck floors really make a difference when it comes to keeping people from slipping around, particularly out at sea where things get slippery fast. The actual design creates rough surfaces that grab better than smooth ones do, so folks aren't sliding all over the place when waves hit. Boat manufacturers typically go with shapes like diamonds or dots because those work pretty well when everything's wet. Most companies run these textures through rigorous testing procedures set by maritime safety organizations before putting them into production. When造船者 (boat builders) install these specially designed textures on decks, they're not just making things look good but actually creating safer working conditions for crew members who spend long hours on deck during rough weather conditions.

Water-Channeling Groove Patterns

The groove patterns used for channeling water are really important when it comes to keeping boat decks free from standing water and preventing slips. These channels work pretty well at moving water off the surface so the deck stays mostly dry even after heavy rain or splashing around. Most boat builders go with either long straight grooves running the length of the deck or diagonal ones that cross at angles because they just seem to work better while looking good too. Marine engineers have tested different designs over time and found that properly spaced grooves can cut down slip accidents by up to 60% according to some recent field tests. Boat owners who want safer decks without sacrificing looks often choose these kinds of patterns since they serve dual purposes both practically and aesthetically speaking.

Marine Safety Certification Standards

Meeting marine safety certification requirements isn't just good practice it's pretty much mandatory if anyone wants safe and reliable boat deck flooring. Organizations such as the American Boat and Yacht Council or ABYC for short, along with the International Maritime Organization, establish strict guidelines that shape how products are made and what consumers end up buying. The actual standards typically involve tests checking how slippery the surface gets when wet and whether the material can hold up under stress without cracking or breaking. Boat manufacturers who follow these rules see real results too. Studies from actual boats on the water show that decks built according to safety specs have way fewer accidents where people slip and fall. That makes sense when we think about spending time on unpredictable seas where stability matters most.

Comfort-Enhanced Deck Flooring Solutions

Pressure-Relieving Cushion Technology

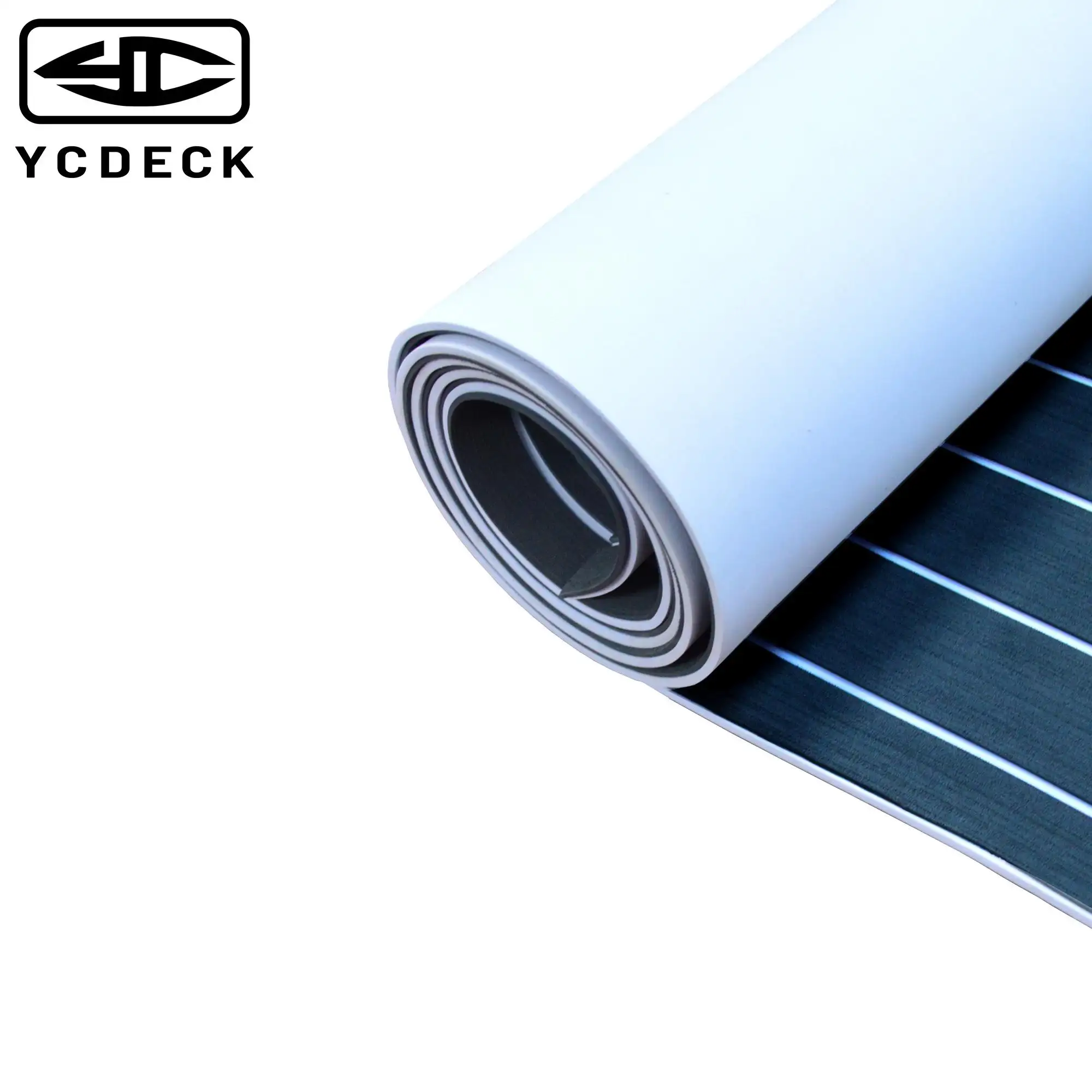

Spending hours out on the water means comfort matters a lot, which is why modern pressure-relieving cushions have become so popular among boaters. Materials like EVA foam and those infused with gel really make a difference in how comfortable people feel while fishing or just enjoying time on the lake. Take EVA foam for instance it's pretty soft but still gives good support, making those long days on board much easier on tired feet. The gel stuff takes things one step further by absorbing shocks better, spreading out body weight so folks don't end up with sore spots after sitting too long. Boat owners who've upgraded to these newer cushioning systems often talk about how much better they feel now, even when they're out there all day. Some say they can finally enjoy their trips without constantly shifting around trying to find a comfortable spot.

Temperature-Regulating Materials

Keeping boat decks comfortable when weather gets extreme really depends on special temperature regulating materials. We're talking about stuff like phase change materials and those breathable fabrics that have taken off in recent years. What makes them work so well? They basically soak up excess heat during hot days then let it go when temps drop at night. Studies show these innovations keep surfaces within a nice range for people spending time outdoors on boats. Boat owners report better experiences overall because their decks don't turn into baking sheets in summer or icy patches come winter. Makes sense why more manufacturers are incorporating these smart materials into new designs these days.

Orthopedic Support Benefits

Deck flooring that provides good orthopedic support makes all the difference when spending hours out on the water. When floors are designed with ergonomics in mind, they actually cut down on foot soreness and keep bodies aligned properly throughout the day. Boat manufacturers have started incorporating things like proper arch support and soft padding layers into their designs, which goes a long way toward reducing stress on muscles and joints. Research from marine safety experts shows that decks with these kinds of supportive features really do make people feel better while aboard and lower chances of developing back problems or other pains later on. Anyone planning to spend time cruising should look for boat flooring options with these comfort enhancing properties, since they offer both immediate enjoyment and protection against potential health problems down the road.

Easy-Cleaning Boat Deck Maintenance

Stain-Repellent Nano-Coatings

Boat owners are discovering that stain repelling nano coatings can totally change how they deal with keeping their deck floors clean. These special coatings form a shield over the deck surface so stains and dirt just don't stick as easily anymore, which means cleaning becomes almost effortless. What makes this work is basically science stuff about changing how water interacts with surfaces using those hydrophobic properties we all learned about somewhere. Some research out there suggests boats with these nano coatings need around 30% less cleaning time than regular decks, though results might vary depending on usage. Beyond saving time, this tech keeps decks looking great all season long while still performing properly when needed most during hot summer days at the marina.

Mold-Inhibiting Antimicrobial Treatments

Mold problems really plague boats and other marine structures, making antimicrobial treatments almost essential if we want safe, clean decks. What these products do basically is create a barrier that stops mold, mildew, and bacteria from taking hold. This protects the deck surface itself while also keeping people healthy who spend time out there. Boat owners have several choices when it comes to mold prevention solutions. Some go with silver ion tech because it works pretty well, while others prefer different organic formulas that also get the job done. The CDC actually points out how important this kind of protection is especially since boats sit in such moist, humid conditions all the time. Using these treatments makes sense for anyone wanting to enjoy their time on the water without worrying about health issues down the road.

FAQ

Q: Why is UV protection necessary for marine flooring?

A: UV protection is essential because prolonged exposure to ultraviolet rays can cause material degradation, fading, and loss of structural integrity. UV-absorbing additives and coatings help extend the lifespan of the flooring by protecting it from sun-induced damage.

Q: How do saltwater-resistant materials benefit boat deck flooring?

A: Saltwater-resistant materials are designed to withstand the corrosive effects of saltwater, reducing the risk of corrosion and material degradation over time. This improves the durability and reliability of the flooring in marine environments.

Q: What role do micro-texture surface designs play in slip resistance?

A: Micro-texture designs enhance grip by increasing friction on the deck surface, reducing slip hazards. These designs are particularly effective in wet conditions, providing safety without compromising aesthetics.

Q: How do stain-repellent nano-coatings aid in maintenance?

A: Nano-coatings create a hydrophobic barrier that repels liquids and grime, making it easier to clean the deck. They significantly reduce cleaning time, ensuring the deck remains visually appealing and functional.