boat deck flooring materials

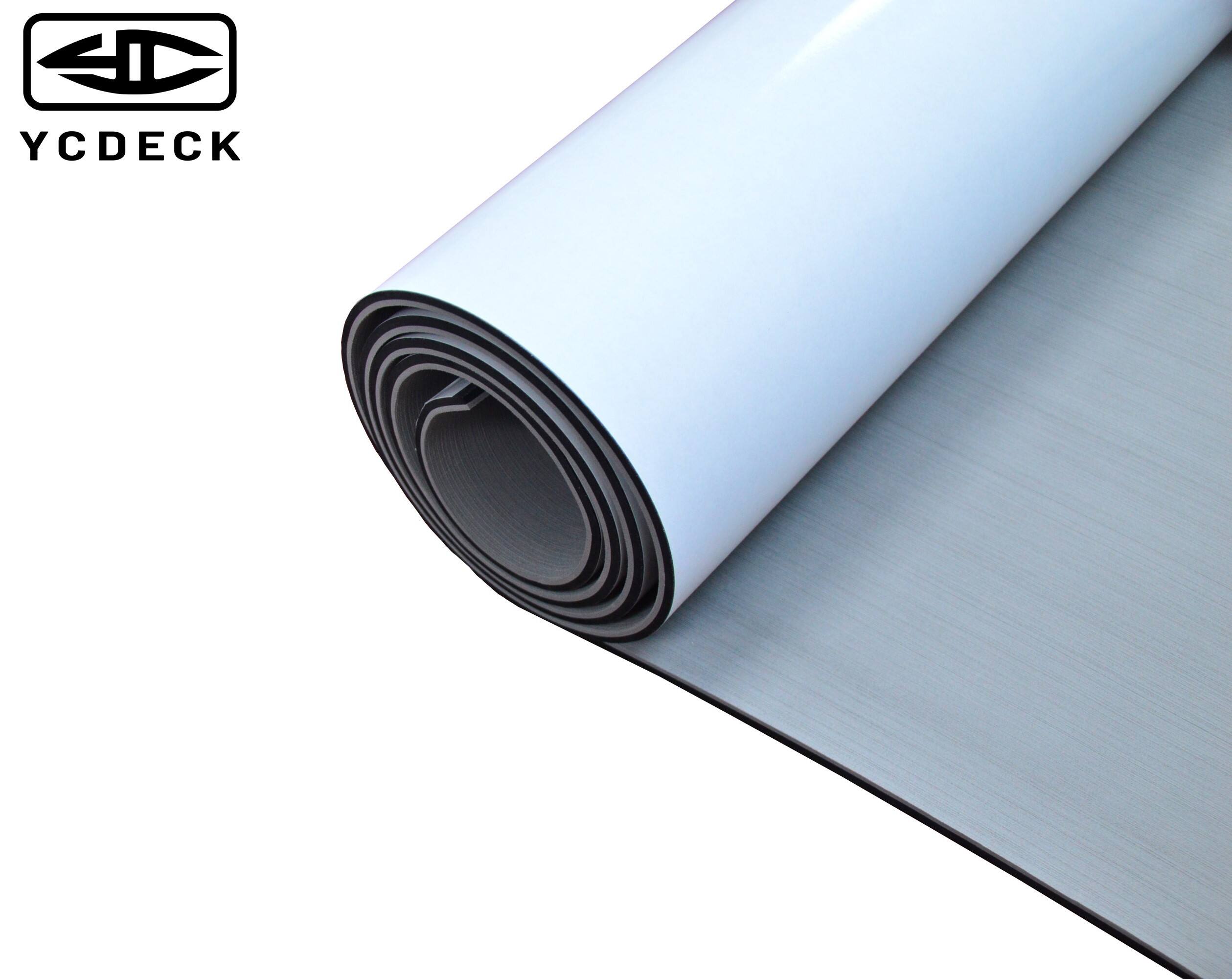

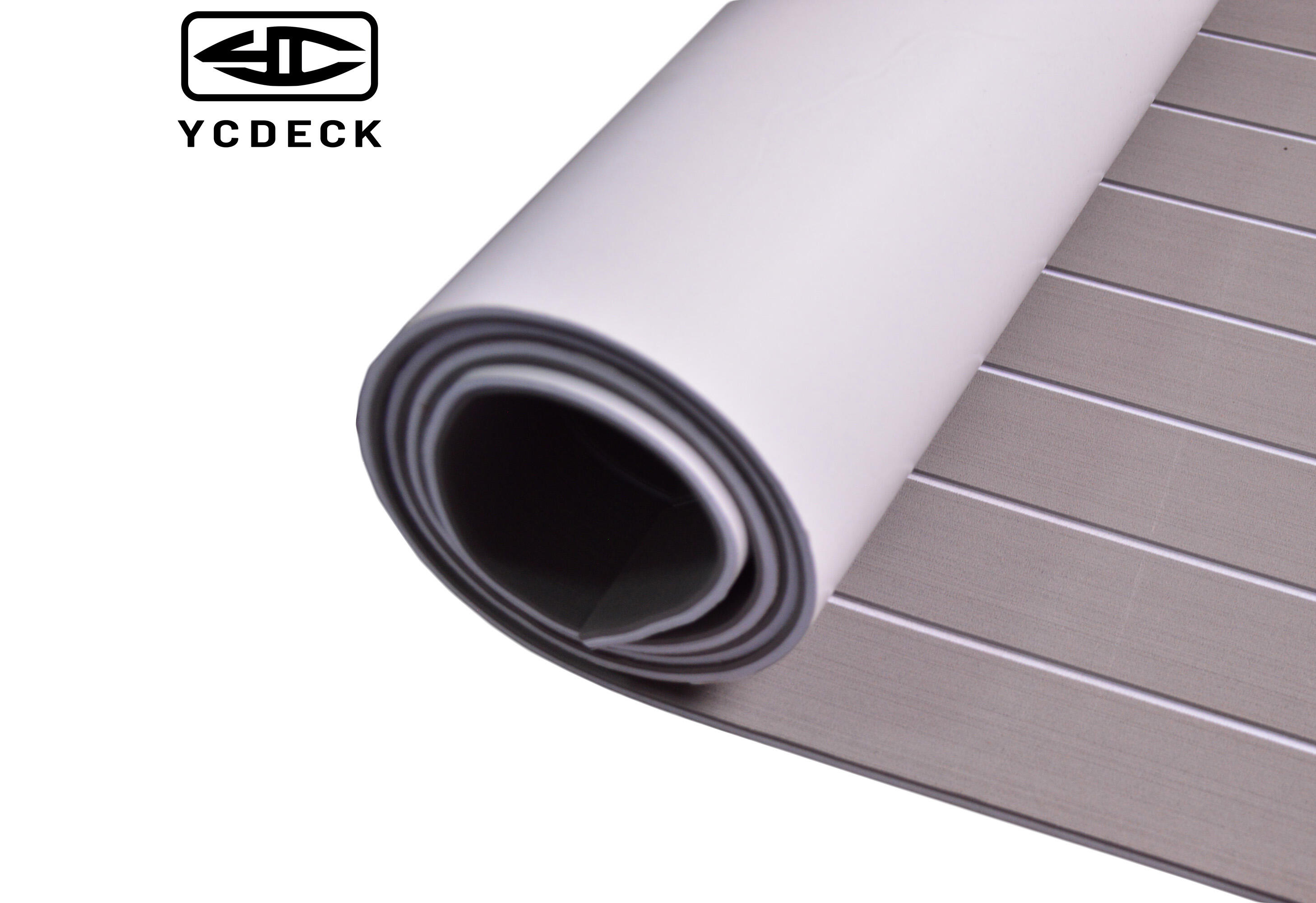

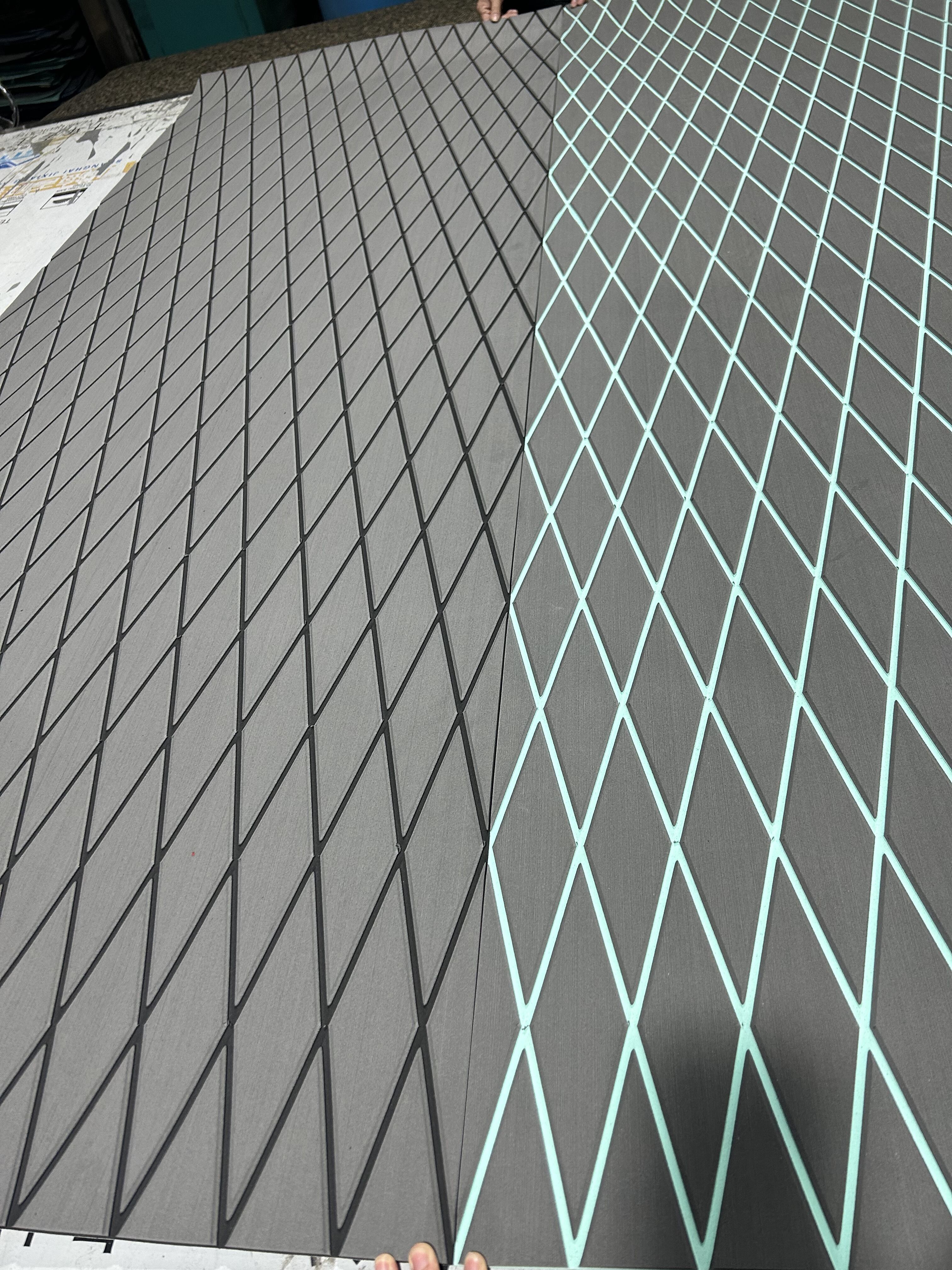

Boat deck flooring materials represent a crucial component in marine vessel construction, combining functionality, durability, and aesthetic appeal. These specialized materials are engineered to withstand harsh maritime conditions while providing safe and comfortable surfaces for passengers and crew. Modern boat deck flooring typically consists of synthetic composites, treated hardwoods, or advanced polymer materials that offer superior resistance to water, salt, UV rays, and temperature fluctuations. The materials undergo rigorous testing to ensure they meet maritime safety standards, featuring non-slip properties even when wet. Contemporary boat deck flooring often incorporates innovative technologies such as heat-reflective properties, antimicrobial treatments, and enhanced impact resistance. These materials are designed for easy installation and maintenance, utilizing advanced joining systems that ensure watertight seals while allowing for thermal expansion and contraction. The applications range from luxury yachts to commercial vessels, with different grades and specifications available to suit various maritime environments and usage requirements.